How Humidity Sensor Works All You Should Know

How Humidity Sensor Works

* What is the humidity sensor, and why is it important for life and production. ?

Humidity is an important environmental parameter that can affect many aspects of our lives, from our health and comfort to the performance of industrial processes and electronic devices. Humidity sensors are devices that measure the amount of water vapor in the air, and they are used in a wide range of applications, including weather monitoring, HVAC systems, food storage, and medical devices, also for consumer, industrial, biomedical, and environmental, etc. applications for measuring and monitoring Humidity.

* How does the humidity sensor work?

In short, the probes of the Humidity Sensor detect changes that alter the temperature or electrical current in the air. Most humidity probes rely on two electrical conductors (electrodes) with a non-conductive polymer film between the electrodes to create an electrical field. The moisture from the surrounding air is collected on the film, which causes a change in the voltage level between the two electrodes. This change is then converted into a digital measurement for you to read the relative Humidity, taking the air temperature into account.

The humidity sensor probe is very important for the total sensor. HENGKO is a professional manufacturer of kinds of sintered metal humidity sensor probes. The main application for some complex condition monitoring. because of their excellent durability and resistance to corrosion, making it suitable for use in harsh environments.

So contact us for details of humidity probes or OEM to custom special humidity sensor probes for your monitor devices and project. Below are some popular humidity probes for the industry humidity sensor. Please check it.

* Humidity Sensors – Classification and Working Principles

Types of Humidity Sensors

Several types of humidity sensors are available on the market, each with advantages and disadvantages. There are 4 types of humidity sensors based on the working principles and sensor materials: capacitive, resistive, thermal conductivity, and psychrometric.

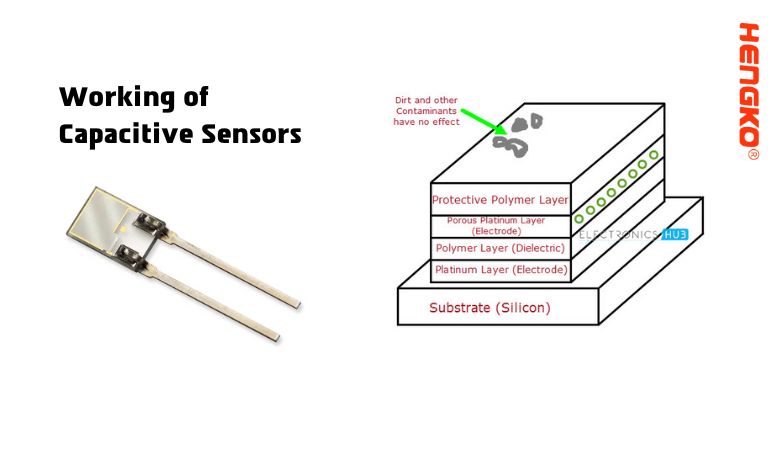

1) Capacitive Humidity Sensors

Capacitive humidity sensors are one of the most commonly used types. They work by measuring changes in the dielectric constant of a material in response to changes in Humidity. The dielectric constant measures a material's ability to store electrical energy in an electric field.

Capacitive humidity sensors typically consist of two electrodes, one coated with a hygroscopic material that absorbs water vapor from the air. When the hygroscopic material absorbs water vapor, it causes a change in the dielectric constant between the two electrodes, which is measured by the sensor.

1. Advantages of Capacitive Humidity Sensors

1.1 The output voltage is near linear.

1.2 They provide stable results over long usage.

1.3 Can detect a wide range of RH.

2. Disadvantages of Capacitive Humidity Sensors

2.1 The distance from the sensor and signaling circuit is very limited.

3. Applications of Capacitive Humidity Sensors

Capacitive Humidity Sensors are used in a wide range of applications, including but not limited to the following:

HVAC Systems

Printers and Fax Machines

Weather Stations

Automobiles

Food Processing

Refrigerators, Ovens, and Dryers

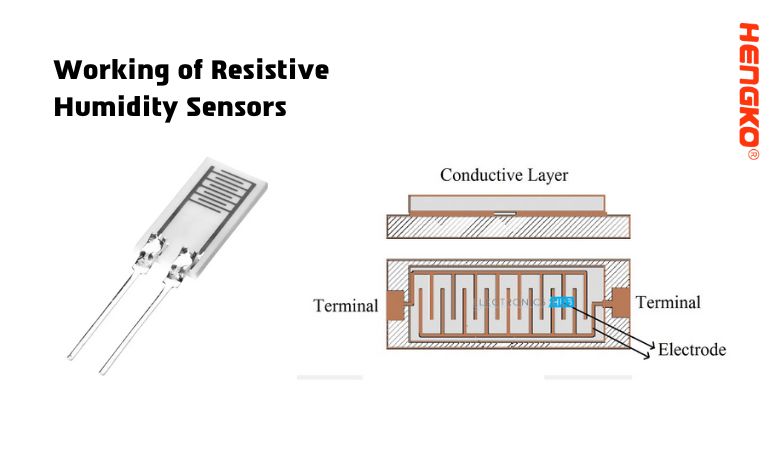

2) Resistive Humidity Sensors

Resistive humidity sensors, also known as hygrometers, work by measuring changes in the electrical resistance of a material in response to changes in Humidity. The most common type of resistive humidity sensor is the polymer-based sensor, which consists of a conductive polymer film that changes its resistance when exposed to water vapor.

When the polymer film absorbs water vapor from the air, it swells and becomes more conductive, which increases the electrical current passing through the sensor. This change in resistance is proportional to the amount of water vapor in the air and can be measured to determine the humidity level.

Advantages of Resistive Humidity Sensors

- Low cost

- Small Size

- The distance between the sensor and signal circuit can be large (suitable for remote operations).

- Highly interchangeable as there are no calibration standards.

Disadvantages of Resistive Humidity Sensors

Resistive Humidity Sensors are sensitive to chemical vapors and other contaminants.

The output readings may shift if used with water-soluble products.

Applications of Resistive Humidity Sensors:

Resistive or Electrical Conductive Humidity sensors are low-cost sensors with relatively small sizes. They are often used in industrial, domestic, residential, and commercial applications.

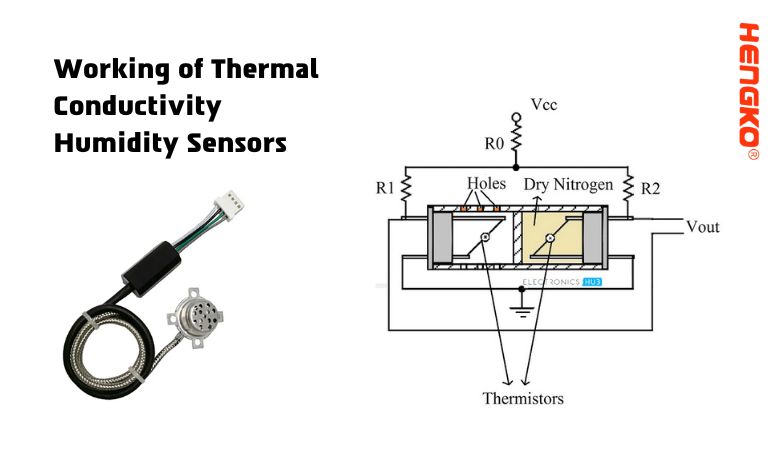

3) Thermal Conductivity Humidity Sensors

Thermal conductivity humidity sensors work by measuring the thermal conductivity of a gas mixture in response to changes in Humidity. They consist of a heated sensing element and a temperature sensor that measures the temperature difference between them.

When the sensing element absorbs water vapor, it reduces its thermal conductivity, which causes a change in temperature that the temperature sensor can measure. This temperature change is proportional to the amount of water vapor in the air and can be used to determine the humidity level.

Advantages of Thermal Conductivity Humidity Sensors

1. Suitable for high-temperature environments and high-corrosive situations.

2. Very durable

3. Higher resolution compared to other types

The disadvantage of Thermal Conductivity Humidity Sensors

Exposure to any gas with thermal properties different than Nitrogen might affect the reading measurement.

Applications of Thermal Conductivity Humidity Sensors

Some of the common applications of Thermal Conductivity Humidity Sensors are:

Drying kilns

Pharmaceutical plants

Owens

Clothes dryers and drying machines

Food dehydration

4) Psychrometric Humidity Sensors

Psychrometric humidity sensors, also known as chilled mirror sensors, measure the temperature at which water vapor condenses on a surface. They consist of a cooled mirror until dew or frost forms on its surface. The temperature at which this condensation occurs is a function of the relative Humidity of the air surrounding the mirror.

1. Advantages of Psychrometric Humidity Sensors

- Accurate measurement: Psychrometric humidity sensors provide highly accurate measurements of humidity levels in the air. They use a combination of temperature and relative humidity to calculate dew point, which gives a more accurate reading of the moisture content in the air.

- Wide range: Psychrometric humidity sensors can measure humidity levels over a wide range, from very dry to highly humid environments.

- Fast response time: These sensors have a fast response time, meaning they can quickly detect changes in humidity levels and provide real-time feedback.

- Durable: Psychrometric humidity sensors are typically built to withstand harsh environments and can be used in a variety of applications.

2. The disadvantage of Psychrometric Humidity Sensors

Cost: Psychrometric humidity sensors can be more expensive compared to other types of humidity sensors. This is due to the complexity of the technology used and the accuracy of the readings provided.

3. Application of Psychrometric Humidity Sensors

- HVAC systems: These sensors are commonly used in heating, ventilation, and air conditioning (HVAC) systems to control humidity levels and maintain a comfortable indoor environment.

- Agriculture: In agriculture, psychrometric humidity sensors can be used to monitor and control the humidity levels in greenhouses, ensuring optimal growing conditions for plants.

- Industrial applications: Psychrometric humidity sensors are also used in industrial settings to measure humidity levels in manufacturing processes or storage facilities where humidity control is critical for product quality and safety.

- Meteorology: These sensors are used by meteorologists to measure and track humidity levels in the atmosphere and to help forecast weather patterns.

* Calibration and Maintenance

Calibration is essential to using humidity sensors to ensure they are accurate and reliable. Most humidity sensors require regular calibration to maintain their accuracy, and the frequency of calibration can depend on the application and the type of sensor.

Several methods for calibrating humidity sensors include reference materials with known humidity levels, such as saturated salt solutions, and specialized calibration equipment that can generate precise humidity levels.

* Applications of Humidity Sensors

Humidity sensors are electronic devices that measure the moisture content or relative humidity in the air. They are used in a wide range of applications, including:

1. HVAC Systems: Humidity sensors are used in HVAC systems to control indoor humidity levels. They help to maintain optimal humidity levels, which can improve indoor air quality and reduce the growth of mold and bacteria.

2. Weather Stations: Humidity sensors are used in weather stations to measure the relative humidity in the air. This information is used to predict weather patterns and to provide accurate weather forecasts.

3. Food Storage: Humidity sensors are used in food storage facilities to monitor the humidity levels and prevent spoilage. They help to maintain the optimal moisture content in food products, which can extend their shelf life.

4. Medical Devices: Humidity sensors are used in medical devices such as nebulizers and oxygen concentrators to monitor and control the humidity levels of the air being delivered to patients.

5. Agriculture: Humidity sensors are used in agriculture to monitor the humidity levels in soil and to control the moisture content in greenhouses. They help to improve crop yields and reduce water consumption.

6. Automotive Industry: Humidity sensors are used in the automotive industry to control the humidity levels inside cars. They can prevent fogging of windows, improve air quality, and provide a comfortable driving experience.

7. Industrial Applications: Humidity sensors are used in various industrial applications, such as drying, coating, and printing. They help to monitor and control the humidity levels in the production process, which can improve the quality of the end product.

Overall, humidity sensors are used in many applications to monitor and control humidity levels. They can improve product quality, reduce energy consumption, and provide a more comfortable and healthy environment for humans and animals.

* How to Select A Humidity Probe

The following are some of the factors that must be taken into consideration when selecting a Humidity Sensor.

1. Accuracy: The accuracy of the humidity probe is an important factor to consider. A more accurate probe will provide more precise humidity measurements. Look for a probe with an accuracy of at least ±2% Relative Humidity (RH).

2. Range: Consider the range of Humidity the probe can measure. Choose a probe with a range that covers the humidity levels you need to measure.

3. Stability: The stability of the probe is important to ensure consistent and reliable measurements over time. Look for a probe that has good long-term stability.

4. Response time: The response time of the probe is important if you need to measure changes in Humidity quickly. Choose a probe with a response time that suits your needs.

5. Environmental conditions: Consider the conditions where the probe will be used. Choose a probe suitable for the temperature and humidity range and any potential exposure to chemicals or other contaminants.

6. Calibration: The probe should be calibrated regularly to maintain accuracy. Consider the ease of calibration and whether the manufacturer provides calibration services.

7. Compatibility: Ensure that the probe is compatible with your measurement system or data logger.

8. Cost: Consider the probe's cost and whether it fits within your budget. Different types of probes are available at various price points, so choose one that meets your needs and budget.

When selecting a humidity probe, consider the accuracy, range, stability, response time, environmental conditions, calibration, compatibility, and cost. Choosing the right probe will ensure accurate and reliable humidity measurements.

7. FAQ about Humidity Sensors

1. What are the different types of humidity sensors?

The most common types of humidity sensors are capacitive, resistive, and thermal conductivity.

2. What is the range of Humidity that humidity sensors can measure?

Most humidity sensors can measure relative Humidity from 0% to 100%.

3. What is the accuracy of humidity sensors?

The accuracy of humidity sensors can vary depending on the type and quality of the sensor. Most sensors have an accuracy range of +/- 2% to +/- 5%.

4. What is the typical response time of a humidity sensor?

The response time of a humidity sensor can vary depending on the type and quality of the sensor. Most sensors have a response time of a few seconds to a few minutes.

5. How often do humidity sensors need to be calibrated?

The calibration frequency of a humidity sensor depends on the type and quality of the sensor, as well as the application. In general, sensors should be calibrated at least once a year.

6. What is the operating temperature range of humidity sensors?

The operating temperature range of humidity sensors can vary depending on the type and quality of the sensor. Most sensors can operate within a range of -40°C to 80°C.

7. Can humidity sensors be used outdoors?

Yes, humidity sensors can be used outdoors, but they should be protected from exposure to direct sunlight and moisture.

8. What are the applications of humidity sensors?

Humidity sensors are used in various applications, including HVAC systems, greenhouses, food processing, manufacturing, and laboratories.

9. Can humidity sensors detect other types of gases?

No, humidity sensors are specifically designed to measure the moisture content of the air and cannot detect other types of gases.

10. How long do humidity sensors last?

The lifespan of a humidity sensor can vary depending on the type and quality of the sensor, as well as the application. Most sensors last between 2 and 10 years, but some can last up to 20 years with proper maintenance and calibration.

If you have any questions or concerns regarding our high-quality humidity sensor or temperature humidity probe, please don't hesitate to contact us. Our team of experts is always happy to help and provide you with any information you need. You can reach us via email at ka@hengko. We are committed to delivering exceptional customer service and timely responses to your inquiries. Thank you for being so interested in our products, and we look forward to hearing from you soon!