What is Sintered Wire Mesh ?

What is Sintered Wire Mesh ?

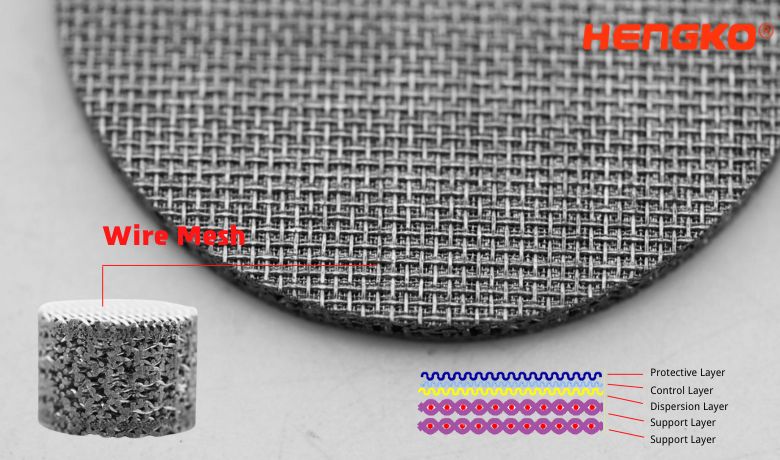

Short to Say, Sintered wire mesh is a type of wire mesh that is made through a process called sintering.

This process involves heating and compressing metal powders at high temperatures to create a solid,

homogenous material. Because of its unique properties and manufacturing process, sintered wire mesh has

several advantages over traditional wire mesh.

There Are 3 Main Special Features of Sintered Wire Mesh :

1. One of the key advantages of sintered wire mesh is its strength and durability. Because it is made from

metal powders fused through sintering, sintered wire mesh has a much higher tensile strength and resistance

to wear and tear than traditional wire mesh. It is ideal for use in various applications where durability and

strength are critical, such as filtration, separation, and support structures.

2. Another advantage of sintered wire mesh is its low permeability. Unlike traditional wire mesh, which can

allow small particles or gases to pass through the gaps between the wires, sintered wire mesh has a much

smaller pore size and can block these particles or gases. It is ideal for filtration applications, where it can

filter out contaminants or impurities from liquids or gases.

3. Sintered wire mesh also has high corrosion resistance, making it ideal for use in applications where

it may be exposed to harsh chemicals or other corrosive substances. It is popular for filtration systems,

where you can filter out impurities from liquids or gases.

4. Another benefit of sintered wire mesh is its versatility. It can be used in many applications, from filtration

and separation to support and reinforcement. For example, it is often used in the automotive industry to

reinforce car bodies and support engine components.

Then Why the As Follows is Have So Many Strong and Special Features ?

Maybe We Can Check How it is Manufactured.

The manufacturing process for sintered wire mesh is relatively simple. First, the

wire is cut into the desired shape and size. Next, the wire is placed into a mold and

subjected to high heat and pressure, which causes the individual wires to fuse.

Once the mesh has cooled, it is removed from the mold and ready for use.

There are a few different types of sintered wire mesh, each with unique properties and characteristics.

For example, some types of sintered wire mesh are made from stainless steel, which is resistant to

corrosion and has a high melting point. Other types of sintered wire mesh are made from other metals,

such as nickel or copper, which have different properties and may be better suited for certain applications.

Overall, sintered wire mesh is a strong, durable, and versatile material widely used in various industrial

and commercial applications. Its resistance to corrosion, high strength, and ability to withstand high stresses

make it a popular choice for many applications, from filtration and separation to reinforcement and support.

So if you also have gas or liquid need to filter, and want to find special filters, maybe you can try our

Sintered Wire Mesh, the super features and reasonable price will help you a lot.

Have any interested and questions, you are welcome to contact us by email ka@hengko.com, we will

send back to you asap within 24-Hours.