What is Sparging: A Comprehensive Guide

What is Sparging ?

In Short, Sparging is a fundamental process employed in various industries where a gas is introduced into a liquid. At its most basic level, it involves the formation of bubbles or the injection of gas into a liquid medium, which increases the surface area for interaction between the gas and the liquid.

One notable application is air sparging in environmental remediation, where air is injected into groundwater to assist in the cleanup of contamination.

This interaction enhances the efficiency of mass transfer—the movement of substances from one phase (gas) to another (liquid). Till now Sparging plays an essential role in numerous processes across a wide range of fields. From brewing beer to purifying water, the method of sparging has wide-reaching implications and uses.

Understanding Sparging: The Basics

At its core, sparging is the process of introducing gas into a liquid medium. This process creates bubbles in the liquid, increasing the surface area for gas and liquid interaction, thereby promoting the transfer of substances between the two phases. This can take the form of transferring a gas into the liquid, or even removing substances from the liquid into the gas phase, depending on the specific application.

Continuous sparging is a method utilized by most commercial breweries and all-grain homebrewers. It highlights efficiency advantages and requires specialized equipment.

The equipment used in sparging can vary significantly based on the requirements of the process. One common design, known as a sparger, typically takes the form of a tube or disk with small holes or porous materials. This allows the gas to be introduced into the liquid as a series of small bubbles, enhancing the effectiveness of the sparging process.

The Science Behind Sparging

The principles behind sparging revolve around the interactions between gases and liquids. When a gas is bubbled through a liquid, it increases the interaction surface area between the two. This in turn facilitates a variety of physical and chemical phenomena, from the dissolving of gases in the liquid to the driving off of volatile substances from the liquid into the gas phase.

One important concept in sparging is that of mass transfer, which is the movement of substances from one phase to another. In the case of sparging, this can involve transferring a gas into the liquid, or removing a substance from the liquid into the gas phase. The creation of small bubbles through the use of a sparger increases the surface area for this mass transfer, making the process more efficient and effective.

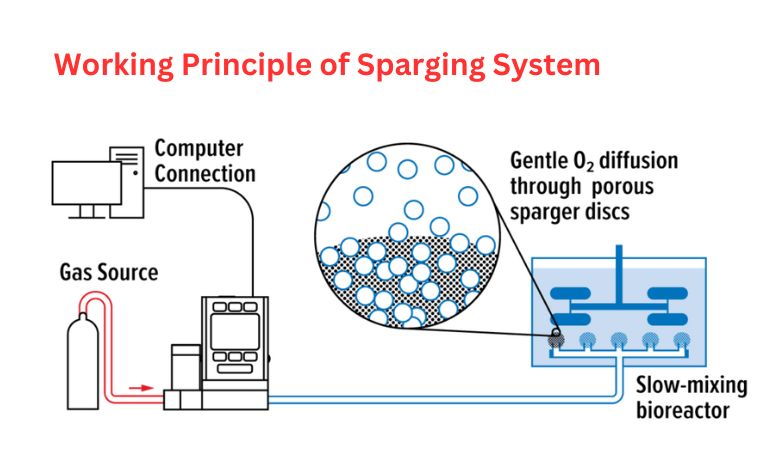

What is the Working Principle of Sparging System ?

The working principle of a sparging system revolves around the concept of mass transfer between two different phases,

typically a gas and a liquid. The main steps involved in a sparging system are as follows:

1. Gas Introduction: The process begins with the introduction of a gas into the sparging system. This is usually done through a sparger, which can be a tube or disk with small holes or a porous material.

2. Bubble Formation: As the gas passes through the sparger, it forms small bubbles. The size of these bubbles can be controlled by adjusting factors such as the pressure of the gas and the design of the sparger.

3. Bubble Dispersion: These bubbles are then dispersed into the liquid medium. As they move through the liquid, they increase the surface area for interaction between the gas and the liquid.

4. Mass Transfer: This interaction facilitates mass transfer between the two phases. Depending on the application, this can involve transferring a gas into the liquid, such as oxygen in a bioreactor, or removing a substance from the liquid into the gas phase, such as volatile organic compounds in water treatment.

5. Bubble Dissipation: As the bubbles rise and reach the liquid surface, the transferred gas is either absorbed by the liquid or, if the purpose was extraction, the undesired gas or volatile compound is released into the atmosphere or further processed.

In homebrewing, the process often involves completely draining the mash tun before continuing with sparging techniques. This method includes extracting runnings for different beers or combining all runnings for a single beer, emphasizing efficiency and the differences between various sparging methods.

The efficiency and effectiveness of a sparging system can be influenced by a variety of factors, including the design of the sparger, the pressure and flow rate of the gas, the properties of the liquid, and the temperature and pressure conditions of the system.

This process, while simple in concept, is critical for a wide range of industrial applications, including brewing, winemaking, water treatment, biotechnology, pharmaceuticals, food and beverage production, and more.

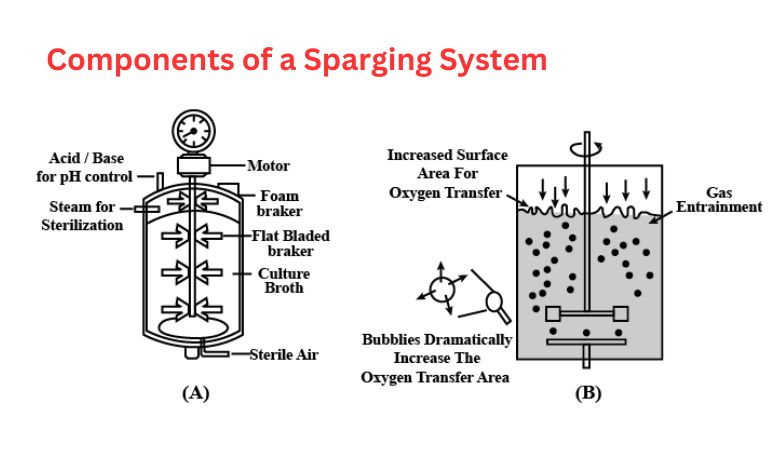

What Are the Components of a Sparging System ?

A sparging system typically consists of several key components, each playing a crucial role in the operation of the system:

1. Gas Supply: This is the source of the gas that will be introduced into the liquid. The choice of gas depends on the specific application of the sparging process.

2. Gas Pressure Regulator: This device adjusts the pressure of the gas being introduced into the system. The pressure needs to be carefully controlled to ensure the efficient creation of small bubbles.

3. Flow Controller: This component controls the rate at which the gas is introduced into the system. Like pressure, the flow rate of the gas can significantly impact the efficiency of the sparging process.

4. Sparger: The sparger is the device that introduces the gas into the liquid. It's typically a tube or disk with small holes or a porous material that allows the gas to be released as a series of small bubbles. The design and material of the sparger can vary depending on the specific requirements of the process.

5. Liquid Medium: This is the liquid into which the gas is introduced. The characteristics of the liquid, such as its viscosity and temperature, can affect the efficiency of the sparging process.

6. Vessel/Container: This is where the sparging process takes place. It contains the liquid medium and must be designed to accommodate the sparger and allow for the efficient dispersion of gas bubbles.

7. Monitoring and Control System: In many industrial sparging systems, sensors and control systems are used to monitor and adjust the process. These can measure parameters like pressure, flow rate, and temperature, allowing for adjustments to be made to optimize the sparging process.

8. Extraction or Outlet System: In many industrial sparging systems, sensors and control systems are used to monitor and adjust the process. These can measure parameters like pressure, flow rate, and temperature, allowing for adjustments to be made to optimize the sparging process.

These components can vary depending on the specific design and application of the sparging system. For example, a sparging system used in a bioreactor may have additional components related to the growth and maintenance of microorganisms.

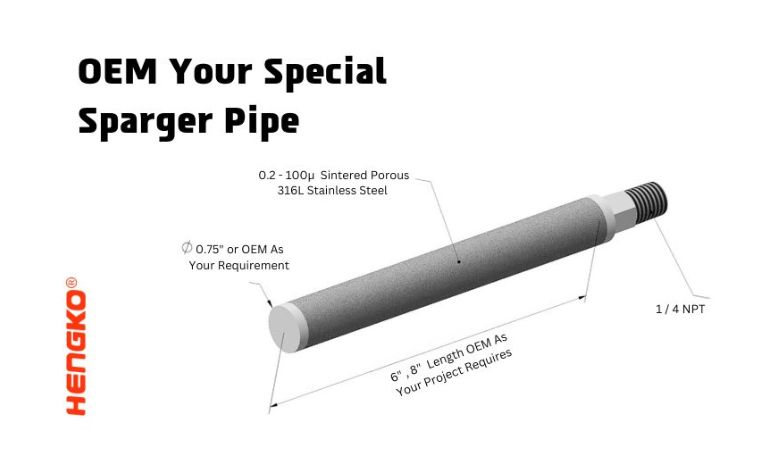

Why Use Sintered Metal Filter to Sparging System ?

Sintered metal filters are used in sparging systems for several reasons:

1. Uniform Pore Size: Sintered metal filters can be produced with very consistent and controlled pore sizes. This uniformity ensures that the gas bubbles produced during sparging are consistent in size, which leads to better mixing and a more efficient process.

2. Durability: Sintered metal filters are extremely durable and resistant to high pressures and temperatures. This makes them ideal for use in industrial sparging systems, which often operate under harsh conditions.

3. Cleanability: Sintered metal filters are easy to clean and can be reused many times, which makes them cost-effective in the long run.

4. Resistance to Corrosion: Sintered metal filters can be made from stainless steel or other corrosion-resistant materials, which is a significant advantage in environments where corrosive substances are present.

5. Ability to Withstand Backpressure: These filters can withstand backpressure, which can be helpful in maintaining the integrity of the system.

For these reasons, sintered metal filters are widely used in applications such as brewing, winemaking, biotechnology, and various chemical processes where sparging systems are employed.

Application of Sparging

1. Sparging in Brewing and Winemaking

The brewing of beer and the making of wine are two fields where sparging is routinely used. During the brewing process, malted barley is soaked in hot water to extract sugars, a process known as mashing. Once this is complete, the mash is sparged by rinsing it with hot water. This helps to wash out any remaining sugars, which are crucial for the subsequent fermentation process that creates alcohol. In homebrewing, the batch sparge method is popular for its simplicity and efficiency. Batch sparging involves adding a fixed amount of hot sparge water to the mash tun, stirring to ensure even extraction, and then draining the mash tun completely before repeating the process. This method is particularly advantageous for beginners and budget-conscious brewers due to its minimal equipment requirements and time efficiency. Batch sparging simplifies the brewing process and is a preferred technique for many homebrewers.

Fly sparging, or continuous sparging, is preferred by many commercial brewers and experienced homebrewers for its efficiency.

Similarly, in winemaking, sparging is used to remove unwanted gases that can affect the quality of the final product. By bubbling an inert gas such as nitrogen through the wine, dissolved gases like oxygen can be displaced and removed. This process can help to extend the shelf life of the wine and maintain its flavor.

The grain bed's depth and structure are crucial in the mashing process, impacting the efficiency of sugar extraction. The mash tun is essential equipment where the mashing occurs, allowing for the extraction of sugars from grains. Using the correct mash water quantity and temperature is vital for efficient sugar extraction. The mashing process creates sugars necessary for fermentation. Pale malt is often used to calculate the necessary grain quantities for achieving the desired original gravity. A sparge arm is used for the even distribution of sparge water over the grains. The temperature and amount of sparge water significantly affect sugar extraction efficiency. Specific gravity is used to determine when to stop sparging to avoid unwanted flavors. Sugary wort, created during sparging, is used in subsequent brewing steps, including boiling with hops and fermentation. Calculating the right amount of water is essential to reach the target volume of wort.

Recent innovations and developments in sparging techniques have helped to further improve these processes. For example, advances in sparger design have led to more efficient mass transfer, enhancing the extraction of sugars during brewing and the removal of gases in winemaking.

2. Sparging in the Biotechnology and Pharmaceutical Industries

In the biotechnology and pharmaceutical industries, sparging plays a critical role in the operation of bioreactors. These devices are used to grow microorganisms that can produce a wide range of products, from pharmaceutical drugs to biofuels.

Oxygen is typically a critical component for the growth of these microorganisms, and sparging is used to ensure that sufficient oxygen is provided. By bubbling oxygen or air through the bioreactor, the microorganisms are ensured to have the oxygen they need to grow and produce their intended products.

The importance of sparging in these industries cannot be overstated. Without effective sparging techniques, the production of many important pharmaceuticals and other products would be much more challenging and less efficient.

3. Sparging in Water Treatment

Sparging also has a significant role in the treatment of water and wastewater. In these applications, sparging can be used to remove volatile organic compounds (VOCs) and other unwanted gases from the water.

Air sparging, a method used in environmental remediation, involves injecting air into groundwater to assist in the cleanup of contamination.

This process works by introducing air or another gas into the water, which can strip out the VOCs and carry them out of the water. This can be a crucial step in ensuring the safety and quality of drinking water, or in treating wastewater before it is released into the environment.

By playing a significant role in maintaining the safety and quality of our water resources, sparging also has a critical role in environmental protection and preservation.

4. Sparging in the Food and Beverage Industry

In the food and beverage industry, sparging is used in several ways. One of the most well-known applications is the carbonation of beverages like soft drinks and beer. This is done by sparging carbon dioxide through the beverage, creating the characteristic bubbles and fizz.

In brewing, the amount of sparge water used should ideally match the volume of the finished beer, which is around 5 gallons.

Beyond beverages, sparging can also be used in other food production processes. For example, it can be used to add or remove flavors and aromas, to aerate mixtures, or to maintain the quality and freshness of various food products.

By enhancing the versatility and quality of food and beverage products, sparging contributes to the range and quality of products available to consumers.

5. Sparging in the Chemical Industry and Metallurgy

The chemical industry and the field of metallurgy are additional areas where sparging has critical applications. In the chemical industry, sparging can be used to introduce gases into liquid-phase reactions, enhancing the efficiency and speed of these reactions.

Homebrewers often add extra grain to compensate for lower extraction efficiencies associated with their chosen brewing method, making it a practical solution to maintain desired beer strength and flavor during the brewing process.

In metallurgy, spargers can be used to introduce gases into molten metals, a process that can help to remove impurities and control the properties of the final product. The metals industry relies heavily on sparging in the production of high-quality metal products.

Through its contribution to efficient chemical reactions and the production of high-quality metals, sparging plays an important role in the operation and success of these industries.

6. Sparging in Aquaculture

Aquaculture, or the farming of fish and other aquatic organisms, is another area where sparging is used. In this field, spargers are used to increase the oxygen content of the water, which is crucial for the health and growth of the aquatic organisms.

By providing a necessary oxygen supply, sparging plays a key role in supporting the productivity and success of aquaculture operations.

7. Challenges and Solutions in Sparging

Despite the many benefits and applications of sparging, the process is not without its challenges. These can include issues with the equipment, such as clogging of the sparger, as well as challenges with achieving optimal mass transfer or managing the gas supply.

However, ongoing technological advancements and optimized operating procedures are providing solutions to these challenges. For example, new sparger designs are being developed that can resist clogging, and advanced control systems are being used to better manage the sparging process.

Through these and other developments, the field of sparging continues to advance and evolve, further solidifying its crucial role across a wide range of industries.

The Future of Sparging

Looking towards the future, it is clear that sparging will continue to have a crucial role across many industries. New developments and advancements in sparging techniques are continually being made, and as these continue, we can expect to see the emergence of new applications and opportunities for sparging.

In addition, as new industries and applications emerge, it is likely that sparging will find new uses in these areas. From supporting the growth of new biotechnologies to helping to solve environmental challenges, the potential for sparging is vast.

In conclusion, sparging is a cornerstone technique that is used across many industries. As we look to the future, it is clear that the continual refinement and application of sparging will play a crucial role in our industrial and technological development.

Are you in need of high-quality, custom-made sintered metal spargers for your sparging system?

Look no further than HENGKO. With our vast industry experience and cutting-edge technology,

we offer tailored solutions that will enhance the performance and efficiency of your projects.

Don't compromise on quality; choose HENGKO for spargers that stand the test of time.

To start a conversation about your unique requirements and how we can meet them, reach out to us

today at ka@hengko.com. Your successful sparging system is just an email away!