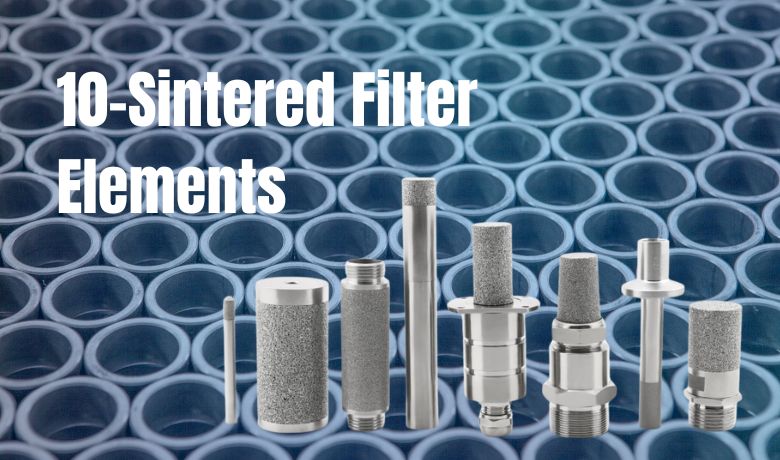

10 Sintered Filter Elements Wide Used for Normal Industrial

Sintered filters are a vital component in many industrial processes.

They are essentially metal filters created by fusing tiny metal particles together, through a process called sintering,

at temperatures below the melting point. This unique structure gives them several advantages:

* High porosity:

They contain a large percentage of empty space, allowing fluids to pass through while trapping unwanted particles.

* Strength and durability:

Sintered filters are strong and can withstand high pressures and temperatures.

* Versatility:

They can be made from various metals and come in different pore sizes to suit a wide range of filtration needs.

These qualities make sintered filters essential for various industrial applications. They are main used in:

* Chemical processing:

Filtering out catalysts, separating desired products from reaction mixtures, and removing contaminants.

* Food and beverage:

Clarifying liquids, removing bacteria, and filtering out unwanted particles.

* Pharmaceuticals:

Sterilizing solutions, filtering out impurities, and controlling particle size in medications.

* Automotive:

Filtering fuels, lubricants, and hydraulic fluids.

* Air and gas filtration:

Removing dust, particles, and contaminants from air and gas streams.

Then as following , I will start to introduce you 10 sintered filters elements popular used in market.

1. Stainless Steel Sintered Filters Elements

Stainless steel sintered filters are a highly versatile and reliable type of filter media used extensively in industrial gas

and liquid filtration applications. They are produced by fusing tiny stainless steel particles together through a sintering

process at a high temperature, below the melting point of the steel. This sintering process creates a rigid, porous metal

structure that offers several key properties:

* High strength and durability:

Stainless steel sintered filters can withstand high pressures and temperatures, making them suitable for demanding industrial environments.

* Excellent corrosion resistance:

Stainless steel is naturally resistant to corrosion from a wide range of chemicals, making them ideal for use with harsh fluids.

* High porosity:

Sintered filters have a large percentage of empty space within their structure, allowing for high flow rates of liquids and gases

while effectively trapping particles larger than the pore size.

* Versatility:

They can be fabricated in various shapes and sizes with a wide range of micron ratings to suit a diverse range of filtration needs.

* Ease of cleaning:

Stainless steel filters can be backwashed or cleaned with solvents, making them reusable for extended periods.

Application :

These properties make stainless steel sintered filters a popular choice for numerous applications in industrial gas and liquid filtration, including:

* Gas filtration:

Removing dust, particles, and contaminants from air and gas streams in various industrial processes, including compressed air filtration,

natural gas filtration, and instrument air filtration.

* Liquid filtration:

Filtering out particles, bacteria, and other contaminants from liquids used in chemical processing, food and beverage production,

pharmaceuticals, and water treatment.

* Oil and fuel filtration:

Removing impurities and contaminants from lubricating oils, hydraulic fluids, and fuels to protect equipment and ensure proper operation.

In addition to these general applications, stainless steel sintered filters are also employed in various specialized industrial filtration processes, including:

* Catalyst recovery: Recovering valuable catalysts from reaction mixtures in chemical production processes.

* Sterilization: Sterilizing solutions and gasses in the pharmaceutical and biotechnology industries.

* Emission control: Removing particulate matter and pollutants from gas streams to comply with environmental regulations.

2. Stainless Steel Sintered Mesh Filters

Stainless steel sintered mesh filters are a type of industrial filter media widely used in the food and beverage industry due to

their exceptional properties. They are manufactured by fusing layers of tiny stainless steel mesh together through a high-temperature

sintering process, below the melting point of the steel. This process creates a rigid, porous metal structure that offers several key advantages:

Main Features :

* High strength and durability:

* Excellent corrosion resistance:

* Ease of cleaning:

These properties make stainless steel sintered mesh filters a popular choice for various applications in food and beverage filtration, including:

Application :

* Clarification of liquids:

* Pre-filtration for membranes:

* Filtration of water:

* Filtration of syrups and oils:

* Air and gas filtration:

3. Bronze Sintered Filters

Bronze sintered filters are another type of metal filter media used in industrial applications. They are manufactured through a similar process

as stainless steel filters, but instead of stainless steel powder, a bronze alloy powder is used as the base material. Here's a breakdown of their

characteristics and manufacturing process:

Main Features :

Characteristics:

* Cost-effective:

2. Molding:

3. Sintering:

4. Deburring and finishing:

Application :

Due to their characteristics, bronze sintered filters find common applications in fluid power and hydraulic systems:

* Filtration of hydraulic fluids:

* Lubrication system filtration:

* Air filtration:

While bronze filters offer a cost-effective solution for many fluid power and hydraulic applications, it's important to

consider their limitations in terms of corrosion resistance compared to stainless steel filters for applications involving harsh chemicals or environments.

4. Sintered Polyethylene Filters:

Overview:

Features and Benefits:

* High chemical resistance to organic solvents and acids.

* Lightweight and cost-effective.

* Biocompatible, making them suitable for some pharmaceutical applications.

* Good for air and gas filtration.

Application

Usage in Pharmaceutical and Biotechnological Industries:

5. Sintered Glass Filters:

Properties of Sintered Glass:

Features:

* Excellent chemical resistance to a wide range of chemicals.

* High thermal stability, allowing for use at high temperatures.

* Inert and can be used for sterile filtration.

* High filtration efficiency for fine particles.

Application:

Typical Applications in Laboratory and Environmental Testing:

6. Nickel-based Sintered Filters:

Composition and Features:

High-temperature capabilities, making them suitable for demanding environments.

Good mechanical strength for high-pressure applications.

Applications

Utilization in High-Temperature and Corrosive Environments:

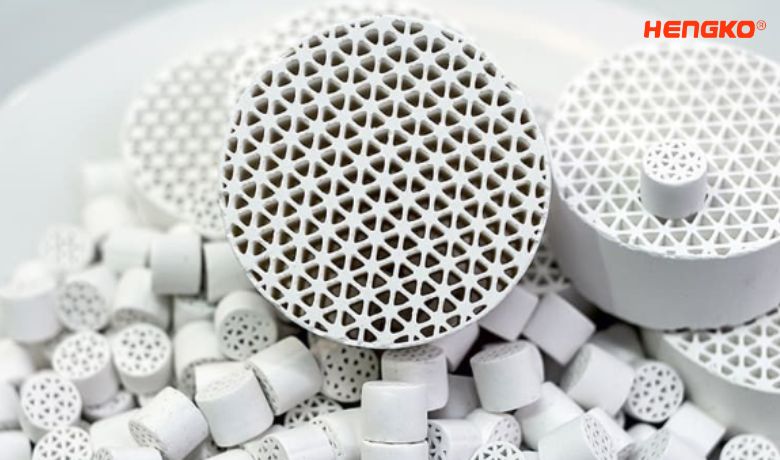

7. Sintered Ceramic Filters:

Key Features and Durability:

Application

Applications in Metal Casting and Air Purification:

8. Titanium Sintered Filters:

Benefits, Features, and Resistance Properties:

Titanium-sintered filters offer a unique combination of high strength, excellent corrosion resistance, and

Application

Preferred Use in Chemical Processing and Marine Industries:

9. Sintered Silver Filters:

Unique Properties, Features, and Effectiveness:

Sintered silver filters are remarkable for their inherent antimicrobial properties.

Applications:

Use in Water Purification and Antimicrobial Filtration:

These filters are ideal for point-of-use water purification systems and applications requiring

10. Sintered Activated Carbon Filters:

Composition, Features, and Filtration Capabilities:

These filters combine a sintered metal structure with embedded activated carbon granules.

Applications in Gas Purification and Odor Control:

Sintered activated carbon filters are employed in air and gas purification systems to remove unwanted gases,

5-Factors You Should Care Choosing the Right Sintered Filter

Selecting the ideal sintered filter for your industrial application requires careful consideration of several factors:

1. Micron rating:

This refers to the size of particles the filter can trap. Choose a micron rating smaller than the particles you want to remove.

2. Material compatibility:

The filter material needs to be compatible with the fluids it will be exposed to. Stainless steel is a popular choice

for its corrosion resistance, but other options like bronze or nickel may be suitable depending on the application.

3. Temperature and pressure:

The filter needs to withstand the operating temperature and pressure of your process.

4. Flow rate:

The filter should allow sufficient fluid flow to meet your process needs while maintaining effective filtration.

5. Cleaning and maintenance:

Consider how easy it will be to clean and maintain the filter. Backwashing or regeneration capabilities may

be important for some applications.

By carefully evaluating these criteria, you can select a sintered filter that optimizes your industrial process

and ensures efficient, reliable filtration.

Contact HENGKO

If you need more detailed advice or wish to discuss your specific filtration needs,

Send your message to us: