Filtration Technology for Different Fluids You Should Know

As we Know Till Now, Filtration technology plays a crucial role in countless aspects of our lives and industry,

impacting everything from the air we breathe to the water we drink and the products we use. It is a process

that separates suspended particles from a fluid (gas or liquid) by passing it through a porous barrier called a filter.

Filtration is vital for various reasons:

* Purification:

Removing contaminants from liquids and gases, making them safe for consumption or use in various processes.

* Protection:

Preventing harmful particles from entering sensitive equipment and systems, ensuring their proper functioning

and extending their lifespan.

* Environmental protection:

Removing pollutants from air and water, contributing to cleaner environments.

* Resource recovery:

Separating valuable materials from fluids, enabling their reuse and reducing waste.

* Product quality:

Ensuring products meet desired purity and clarity standards.

In the realm of filtration technology, our primary focus centers on

two distinct mediums: Gas and Liquid.

However, it's crucial to recognize that not all gases and liquids are alike, and as such, they require tailored

filtration methods to ensure optimal purity and quality. This tailored approach is key to obtaining the best

possible gas or liquid for subsequent manufacturing processes.

By understanding and implementing specific filtration techniques for different types of gases and liquids,

we can significantly enhance the efficiency and effectiveness of our manufacturing endeavors.

Gas Filtration

Gas filtration is the process of removing unwanted particles and contaminants from a gas stream. It plays

a vital role in various applications such as air purification, industrial gas processing, and protecting sensitive

equipment. Here are some of the main types of gas filtration technologies:

1. Mechanical Filters:

These filters capture particles based on their size. They typically use a mesh or membrane with pores that

are smaller than the particles to be removed. As the gas passes through the filter, the particles are trapped

on the surface of the membrane.

Types of Mechanical Filters:

* Depth filters:

These have a thick, fibrous structure that traps particles within their layers.

They are effective for removing larger particles but can have a high pressure drop.

* Membrane filters:

These have a thin, porous membrane that allows gas molecules to pass through while retaining larger particles.

They are typically more efficient than depth filters and have a lower pressure drop.

2. Adsorption Filters:

These filters use materials like activated carbon to trap molecules. The adsorbent material has a large

surface area with pores that attract and hold gas molecules. As the gas passes through the filter,

the unwanted molecules are adsorbed onto the surface of the adsorbent.

Types of Adsorption Filters:

* Activated carbon filters:

These are the most common type of adsorption filter. Activated carbon is a

highly porous material that can adsorb a wide range of gases.

* Molecular sieve filters:

These use zeolite materials to selectively adsorb specific molecules.

3. Chemical Filters:

These filters employ reactive materials to neutralize harmful gases. The chemical reaction converts the

harmful gas into a harmless product that can be safely released or disposed of.

Types of Chemical Filters:

* Scrubber filters: These use a liquid solution to absorb and react with the unwanted gas.

* Chemisorption filters: These use solid materials to react with and remove the unwanted gas.

Applications of Gas Filtration:

* Air purification:

Removing dust, allergens, and pollutants from indoor and outdoor air.

* Industrial gas processing:

Separating impurities from oil and gas to produce clean fuels.

* Protecting sensitive equipment:

Preventing harmful particles from entering sensitive equipment.

* Medical applications:

Supplying clean air for medical procedures.

* Environmental protection:

Removing pollutants from industrial emissions.

Choosing the right gas filtration technology depends on several factors, including:

* The size and type of particles to be removed

* The desired level of purity

* The flow rate of the gas

* The cost and complexity of the process

It's important to consult with a qualified filtration specialist to determine the best type of filter for your

specific needs.

Liquid Filtration

Liquid filtration is the process of removing unwanted particles and contaminants from a liquid stream.

It is essential for various applications, including water treatment, chemical processing, and food and

beverage production. Here are some of the main types of liquid filtration technologies:

1. Surface Filters:

These filters trap particles on the surface of the filter medium. They typically use a mesh or screen with

pores that are smaller than the particles to be removed. As the liquid passes through the filter, the particles

are trapped on the surface of the screen.

Types of Surface Filters:

* Screen filters:

These are the simplest type of surface filter. They are made of a metal mesh with openings

that are large enough to allow the liquid to pass through but small enough to trap large particles.

* Cartridge filters:

These contain pleated filter media made of paper, cloth, or other materials.

They are available in a variety of pore sizes to remove different sizes of particles.

2. Depth Filters:

These filters capture particles within the matrix of the filter material. They are typically made of thick,

fibrous materials that trap particles within their layers. Depth filters are effective for removing small

particles but can have a high pressure drop.

Types of Depth Filters:

* Depth filters: These are made of materials like cellulose, glass fibers, or synthetic fibers.

They are effective for removing a wide range of particle sizes, including bacteria and viruses.

* Wound filters: These are made by winding a fibrous material around a core.

They are available in a variety of sizes and pore sizes.

3. Membrane Filters:

These filters use thin membranes with specific pore sizes to allow only molecules smaller than the pores

to pass through. They are effective for removing very small particles, including bacteria, viruses,

and dissolved molecules.

Types of Membrane Filters:

* Microfiltration:

pore sizes of 0.1 to 10 microns and are used to remove bacteria, parasites, and other large particles.

* Ultrafiltration:

pore sizes of 0.01 to 0.1 microns and are used to remove viruses, proteins, and other smaller particles.

* Nanofiltration:

pore sizes of 0.001 to 0.01 microns and are used to remove dissolved molecules like salts and sugars.

* Reverse osmosis:

the smallest pore sizes of all membrane filters (0.0001 microns) and are used to remove almost

all dissolved molecules from water.

Applications of Liquid Filtration:

* Water treatment:

Removing impurities from drinking water, wastewater treatment.

* Chemical processing:

Separating reactants, products, and catalysts during chemical reactions.

* Food and beverage industry:

Clarifying and purifying beverages, removing solids from oils, and separating components

in food processing.

* Pharmaceutical production:

Sterilizing medications and purifying biological products.

* Oil and gas processing:

Separating water and other impurities from oil and gas.

Choosing the right liquid filtration technology depends on several factors, including:

* The size and type of particles to be removed

* The desired level of purity

* The flow rate of the liquid

* The chemical compatibility of the liquid and the filter material

* The cost and complexity of the process

So It's important to consult with a qualified filtration specialist to determine the best type of filter for your

specific needs.

Special Gases and Special Liquids Filtration

Filtration of special gases and liquids presents unique challenges due to their hazardous properties,

high purity requirements, or complex compositions. Here's a breakdown of the challenges and

solutions involved:

Challenges:

* Corrosive or reactive gases and liquids:

These can damage traditional filter materials, requiring specialized materials like Hastelloy or PTFE.

* High purity requirements:

In industries like pharmaceuticals and semiconductors, even trace impurities can significantly

impact product quality.

Achieving and maintaining such high purity levels requires stringent filtration methods.

* Complex compositions:

Some fluids have multiple components with varying sizes and properties,

making separation and filtration more complex.

Solutions:

* Specialized materials:

Filters made of corrosion-resistant materials like metal alloys, polymers like PTFE (Teflon), or ceramics

can withstand harsh chemicals and aggressive environments.

* Stringent filtration methods:

Techniques like multi-stage filtration, ultrafiltration, and nanofiltration can achieve high levels of purity

by removing even the smallest particles and contaminants.

* Advanced filter designs:

Membrane filters with precise pore sizes or specially engineered cartridges can selectively remove

specific components based on their size and properties.

* Process control and monitoring:

Real-time monitoring of pressure, flow rate, and purity levels helps ensure optimal performance and

timely intervention in case of any deviations.

* Adsorption and chemical filtration:

In cases where complex separation is needed, additional techniques like adsorption with activated

carbon or chemical filters can be employed to remove specific contaminants.

Advanced Filtration Technologies:

* Gas Chromatography:

Separates and identifies volatile components in gas mixtures using a column filled with a special adsorbent material.

* High-Performance Liquid Chromatography (HPLC):

Utilizes high pressure to separate components in liquids based on their interactions with a stationary phase.

* Membrane Distillation:

Uses membranes to separate components based on their volatility, allowing for energy-efficient separation of high-purity liquids.

* Electrostatic Precipitation:

Employs an electric field to charge particles, attracting them to collecting plates and effectively removing them from the gas stream.

Examples of Special Gases and Liquids:

* Hydrofluoric acid:

Highly corrosive, requires specialized PTFE filters.

* Semiconductor process chemicals:

Extremely high purity required, necessitating multi-stage filtration with stringent monitoring.

* Biopharmaceuticals:

Sensitive to impurities and require specialized filters for purification.

* Toxic gases:

Need specialized filters and handling procedures to ensure safety.

Importance:

Effectively filtering special gases and liquids is crucial for ensuring the safety, quality, and performance

of various processes across industries. Improper filtration can lead to product contamination,

equipment damage, safety hazards, and environmental risks.

High Temperature and High Pressure Gases Filtration

High-temperature and high-pressure (HTHP) gas filtration poses unique challenges due to the extreme

conditions that require specialized design and material considerations.

Here's a breakdown of the key aspects:

Design Considerations:

* Pressure resistance:

Filter housings and elements must withstand significant pressure without deformation or rupture.

* Temperature tolerance:

Materials need to retain their strength and integrity at high temperatures without melting or degrading.

* Corrosion resistance:

The filter components should be resistant to corrosion from the specific gas being filtered.

* Flow efficiency:

The design needs to minimize pressure drop while maintaining high filtration efficiency.

* Cleanability and regeneration:

Some filters require cleaning or regeneration to maintain performance, and the design should accommodate these processes.

Material Considerations:

* Metal alloys:

Stainless steel, Hastelloy, and Inconel are common choices due to their high strength, temperature resistance, and corrosion resistance.

* Ceramics:

Alumina, zirconia, and silicon carbide are ideal for extremely high temperatures and offer excellent chemical resistance.

* Glass fibers:

Borosilicate glass fibers offer high temperature resistance and good filtration efficiency.

* Special polymers:

PTFE and other high-performance polymers can be used for specific applications requiring chemical resistance and flexibility.

Technological Innovations:

Several innovative technologies have emerged to address the challenges of HTHP gas filtration:

* Ceramic filter elements:

These offer high temperature resistance (up to 1800°C) and can be designed with specific pore sizes

to achieve desired filtration performance.

Made of porous metal powders, these filters offer high strength, good temperature resistance,

and can be cleaned and regenerated efficiently.

* Self-cleaning filters:

These incorporate mechanisms like back pulsing or reverse flow to automatically remove accumulated

contaminants, reducing maintenance requirements.

* Membrane filters:

High-temperature resistant membranes with precise pore sizes can be used for high-efficiency

filtration of specific gas components.

Examples of HTHP Filters:

- Sintered metal filters:

- Ceramic filter elements:

- High-temperature membrane filters:

Applications:

HTHP gas filtration is crucial in various industries:

* Power generation:

Removing particulate matter from gas turbine inlet air to protect the turbines and improve efficiency.

* Chemical processing:

Filtering hot gases and vapors in chemical reactions to remove impurities and ensure product quality.

* Petrochemical industry:

Separating components in gas streams from refining and processing operations.

* Steel and metal industry:

Filtering hot flue gases from furnaces and incinerators to control air pollution.

* Aerospace:

Protecting sensitive equipment from dust and contaminants in high-temperature environments.

Conclusion:

High-temperature and high-pressure gas filtration requires careful design and selection of

materials to ensure safe and efficient operation.

By understanding the challenges and utilizing advanced technologies, industries can effectively

filter HTHP gases for various applications, contributing to improved performance, environmental

protection, and operational safety.

High Temperature and High Pressure Liquids Filtration

High-temperature and high-pressure (HTHP) liquids present unique challenges for filtration due to

the extreme conditions that can significantly impact the process.

Here's a breakdown of the key difficulties and solutions:

Challenges:

* Viscosity changes:

As temperature increases, the viscosity of liquids decreases, making it easier for some contaminants

to pass through the filter.

* Thermal expansion:

Both the liquid and the filter components expand at different rates due to temperature changes, potentially

affecting the filtration performance and causing leaks.

* Pressure effects:

High pressure can compact the filter media, reducing its porosity and filtration efficiency. Additionally,

it can cause stress on the filter housing and seals, leading to potential failures.

* Chemical compatibility:

The high temperatures and pressures can increase the chemical reactivity of the liquid, requiring special

materials for the filter to ensure its integrity and prevent contamination.

* Corrosion:

The combination of high temperature, pressure, and potentially corrosive liquids can accelerate the corrosion

of filter components, reducing their lifespan and compromising their performance.

Solutions and Techniques:

To overcome these challenges, several solutions and techniques are employed in HTHP liquid filtration:

* Specialized filter media:

High-temperature resistant materials like stainless steel mesh, sintered metal powder, and ceramic

fibers are used to withstand the extreme conditions.

* Multi-stage filtration:

Implementing multiple filters with different pore sizes can address various particle sizes and achieve

high overall efficiency.

* Temperature control:

Maintaining a stable temperature throughout the filtration process helps mitigate the effects of thermal

expansion and viscosity changes.

* Pressure-resistant housings:

Robust housings made of high-strength materials like stainless steel or titanium are designed to

withstand the high pressure and prevent leaks.

* Chemical-resistant seals:

Special seals made of materials like Teflon or Viton are used to ensure compatibility with the

specific liquid and prevent leaks even at high temperatures and pressures.

* Self-cleaning filters:

These incorporate mechanisms like back pulsing or reverse flow to remove accumulated contaminants

automatically, reducing maintenance requirements and ensuring consistent performance.

Examples of HTHP Liquid Filters:

* Sintered metal filters:

* Ceramic filter elements:

* Metal mesh filters:

* High-temperature membrane filters:

Applications:

HTHP liquid filtration plays a vital role in various industries:

* Chemical processing:

Separating components in chemical reactions, filtering out solids and impurities.

* Petrochemical industry:

Processing crude oil and natural gas, filtering out contaminants before further processing.

* Power generation:

Filtering steam and water in boilers and turbines to improve efficiency and prevent equipment damage.

* Steel and metal industry:

Filtering molten metals and alloys to remove impurities and achieve desired properties.

* Food and beverage industry:

Sterilizing liquids and removing contaminants to ensure product safety and quality.

Conclusion:

Filtering high-temperature and high-pressure liquids requires specialized technology and careful

consideration of the extreme conditions involved. By implementing the appropriate solutions and techniques,

HTHP filtration can be effectively performed in various industries, ensuring product quality, safety, and

operational efficiency.

And at the end, we list some special gas and liquid need to make filtration

Special Gases and Liquids Needing Filtration in Industrial Manufacturing

Special Gases:

* Hydrofluoric acid (HF):

Highly corrosive to most materials, requiring specialized filters made of Teflon (PTFE) or other

resistant polymers.

* Silane (SiH4):

Highly flammable and pyrophoric, requiring special handling procedures and filters designed for

safe operation.

* Chlorine (Cl2):

Toxic and corrosive, requiring special materials like Hastelloy or Inconel for filters and handling equipment.

* Ammonia (NH3):

Toxic and corrosive, requiring filters made of stainless steel or other resistant materials.

* Hydrogen sulfide (H2S):

Highly toxic and flammable, requiring special filters and safety precautions.

* Sulfur dioxide (SO2):

Corrosive and toxic, requiring filters made of stainless steel or other resistant materials.

Special Liquids:

* High-purity chemicals:

Used in semiconductor and pharmaceutical industries, demanding extremely high purity levels and

specialized filters like membrane filters or multi-stage filtration systems.

* Biopharmaceuticals:

Sensitive to impurities and require special filters designed for purification and ensuring product quality.

* Molten metals and alloys:

High temperatures and potential for solidification require specialized filters made of refractory materials like

ceramics or high-temperature alloys.

* Molten salts:

Highly corrosive and require special materials like Hastelloy or Inconel for filters and handling equipment.

* Slurries and pastes:

High viscosity and abrasive nature require specific filter designs and materials to ensure efficient filtration

and prevent clogging.

* Toxic and hazardous liquids:

Require special handling procedures and filters designed to prevent leaks and exposure to harmful substances.

Note:

This is not an exhaustive list, and the specific type of special gas or liquid requiring filtration will depend on

the specific industrial manufacturing process.

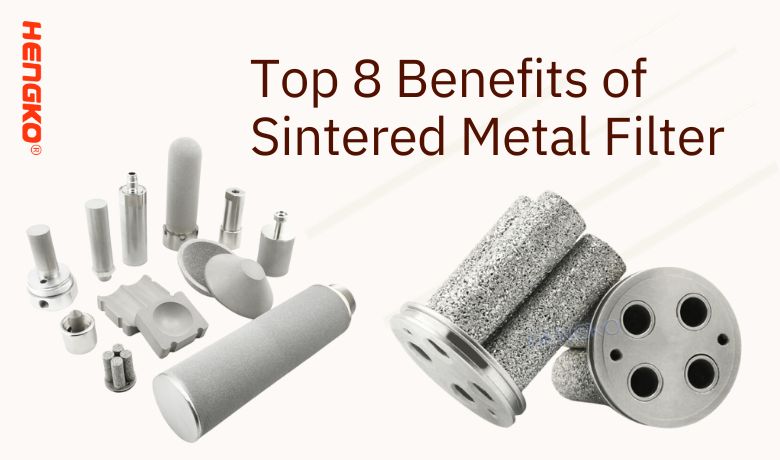

Do You Have a Special Gas or Liquid Filtration Project?

HENGKO understand that every filtration challenge is unique, especially when it comes to handling special

gases and liquids. Our expertise in customizing filters to meet specific needs sets us apart in the industry.

If you're in need of specialized filtration solutions, we're here to help. Whether it's for a unique application

or a challenging environment, our team is equipped to design and manufacture filters that meet your

exact requirements.

Don't let filtration challenges slow you down. Reach out to us for OEM (Original Equipment Manufacturer)

services that are tailored to your project's specific needs.

Contact us today at ka@hengko.com to discuss your project and how we can help bring your ideas to reality.

We're committed to providing high-quality, customized filtration solutions that help you achieve optimal results.