Full Guide about What is Air Sparging

Air sparging plays an integral role in the process, and today, you and I are going to uncover what it is, why it's important, and how it works. By the end of this journey, you'll have a comprehensive understanding of air sparging, its principles, equipment, application, and much more.

Do You Know the process of air sparging? while scientific and somewhat complex, is fascinating and highly beneficial in today's world, where maintaining our environment is of utmost importance. So, whether you're a student, a professional in the field, or someone simply curious about environmental processes, let's dive into the captivating world of air sparging.

Understanding Air Sparging: Definition and Basic Principle

Air sparging is an in situ remediation technology used to treat contaminated soil and groundwater. This technique involves injecting air into the ground, often under pressure, to promote volatilization and biodegradation of contaminants.

The basic principle behind air sparging is quite simple. Imagine the effervescence that occurs when you open a soda bottle. The process that leads to the formation of those bubbles is similar to what happens during air sparging. The injected air acts as those bubbles, pushing the contaminants up through the soil where they can be captured and treated, effectively cleaning the groundwater and soil from the bottom up.

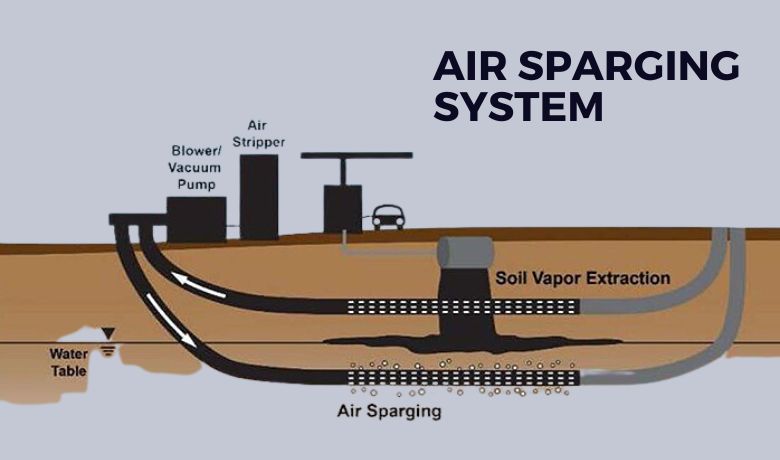

The beauty of air sparging is that it can work hand-in-hand with soil vapor extraction. While air sparging targets contaminants below the water table, soil vapor extraction takes care of contaminants in the unsaturated zone, the area above the water table. When used together, they provide a comprehensive solution to soil and groundwater contamination.

In essence, air sparging is a bit like an invisible, underground janitor, tirelessly working to clean up our environment. And that, my friends, is only the tip of the iceberg. As we delve further into the specifics of air sparging, you'll understand just how significant and fascinating this process truly is.

Main Features of Air Sparger

Air spargers or Gas sparger play a significant role in various applications, from environmental remediation to industrial processes. They are devices designed to disperse gases into liquids or solid mediums, aiding in everything from the breakdown of pollutants to the stimulation of microbial activity. Here are some of the main features of air spargers:

-

Design and Material: Air spargers are typically made of robust materials such as stainless steel, PVC, or ceramic, ensuring they can withstand a variety of environments and applications. Their design often includes a porous section or a series of small outlets to create fine bubbles when air or gas is introduced.

-

Size of Bubbles: A critical feature of air spargers is their ability to produce small bubbles. The smaller the bubbles, the larger the surface area available for gas exchange, improving efficiency in processes like air sparging and biological reactions in fermenters or bioreactors.

-

Distribution Pattern: Air spargers are designed to distribute the bubbles evenly throughout the medium, ensuring uniform gas dispersion. This distribution aids in the efficiency of the process, whether it's contaminant volatilization or oxygenation in a fermentation tank.

-

Durability and Maintenance: Given the environments in which they operate, air spargers need to be durable and resistant to blockages. Many designs include self-cleaning features or are made from materials that resist clogging, ensuring long-term efficiency and minimizing maintenance needs.

-

Adaptability: Air spargers are adaptable to various applications. They can be tailored to the specific needs of a project, considering factors like the required bubble size, pressure, flow rate, and the nature of the medium into which the gas is being introduced.

-

Integration with Systems: Air spargers are usually part of a broader system, such as an air sparging system for soil and groundwater remediation or a bioreactor for pharmaceutical production. They are designed to integrate seamlessly with these systems, contributing to their overall efficiency and success.

In summary, the main features of air spargers – their design, the size of the bubbles they produce, their distribution pattern, durability, adaptability, and integration with broader systems – all contribute to their critical role in various environmental and industrial processes.

Air Sparging Equipment and System Design

Now that we have an understanding of what air sparging is and the principle behind it, let's delve into the tools of the trade. It might surprise you, but the equipment for air sparging is not overly complex.

A standard air sparging system consists of an air compressor, an air delivery system, and a network of injection wells, aptly named air sparge wells. The compressor, the heart of the system, generates the pressurized air required for the process. The air delivery system, akin to the veins, guides the air from the compressor to the injection wells, which serve as gateways to the soil and groundwater beneath.

Designing an air sparge system requires careful consideration of the site-specific conditions, such as soil type, depth to groundwater, and the nature of the contaminants. A well-designed system will ensure effective delivery of air to the contaminated zone and optimize the remediation process. In essence, the design of the air sparging system is a critical determinant of its success.

The Air Sparging Process

So, how does this all come together in practice? Let's walk through the air sparging process.

First, the air compressor pushes air into the injection wells, which are drilled into the ground at strategic locations to reach the contaminated zone. Once the air is introduced into the groundwater, it rises, much like the bubbles in your soda, volatilizing the contaminants along its way.

As these contaminants change from a liquid to a gas state, they move more freely, migrating from the saturated zone (below the water table) to the unsaturated zone (above the water table). This is where the companion technology of soil vapor extraction comes into play, capturing and treating the vapor-phase contaminants.

However, the process is not always as straightforward as it might sound. Variables such as soil permeability, the type and concentration of contaminants, and groundwater depth can affect the air sparging process. The key to a successful air sparging operation is adaptability and a keen understanding of these variables.

For instance, denser soils might require higher pressures to effectively distribute the air, while lighter, sandy soils could be successfully treated with lower pressures. Similarly, some contaminants might be more readily volatilized than others, influencing the process's effectiveness and duration.

Despite these challenges, air sparging is a proven and effective technique for soil and groundwater remediation. It’s like a breath of fresh air, literally and figuratively, to the contaminated underground world.

The Role of Air Spargers in Various Environments

Air spargers, while relatively simple in concept, find their utility in a range of environments. For instance, within a bioreactor – a vessel in which biological reactions are carried out – an air sparger serves an invaluable function. It introduces fine bubbles of air or other gases, providing the oxygen necessary for the reactions and promoting mixing of the medium.

In a fermenter, used for growing microorganisms to produce products like beer or pharmaceuticals, the role of an air sparger is similar. It introduces the necessary oxygen for the microorganisms to grow and thrive, aiding in the fermentation process.

Tank operations also often require air spargers. Whether it's mixing different liquids, ensuring uniform temperature, or promoting chemical reactions, air spargers contribute significantly by creating a stream of tiny bubbles that facilitate these processes.

Lastly, let's touch on a fascinating application – the air sparged hydrocyclone. In mineral processing, this specialized equipment uses air sparging to increase the separation efficiency of different minerals, making it an innovative and effective application of the air sparging concept.

Understanding Air Sparging and Soil Vapor Extraction

By now, you've got a good understanding of air sparging as a standalone technique. But remember when we talked about it being like a tag-team wrestler? Its partner in the ring is soil vapor extraction (SVE), a complementary technique that makes this remediation team a powerful force in treating soil and groundwater contamination.

Air sparging and soil vapor extraction together form a comprehensive approach to remediation. While air sparging focuses on the saturated zone beneath the water table, SVE targets the unsaturated zone above it.

Air sparging promotes the volatilization of contaminants, converting them into gas form. This contaminated gas then migrates into the unsaturated zone, where SVE comes into play. SVE systems extract this contaminated vapor, which is then treated and disposed of safely.

The benefits of combining these two techniques are substantial. It allows for a more complete and efficient remediation, tackling contamination in both soil and groundwater, and across both saturated and unsaturated zones.

Practical examples of this technique abound, from treating petroleum leaks at gas stations to cleaning up industrial spills. The combination of air sparging and SVE has proved to be a reliable, cost-effective solution to a problem that could otherwise have detrimental environmental impacts.

The Costs of Air Sparging

It's important for you to understand the economic aspect of air sparging as well. While this remediation technique provides significant environmental benefits, like any process, it does come with costs.

The costs of air sparging can be influenced by several factors. Site-specific conditions such as soil type, depth of groundwater, the nature and extent of contamination, and local regulatory requirements, can all play a role in determining the overall expenses. The size and complexity of the system required, including the number and depth of air sparge wells, also factor into the cost.

Budgeting for air sparging involves careful planning, a thorough site assessment, and the design of a system tailored to the specific needs of the project. While the initial costs might seem substantial, it's important to weigh these against the potential costs of neglecting contamination – which can range from regulatory fines to lasting environmental damage.

Moreover, air sparging offers significant economic benefits. It's an in-situ technique, meaning it treats contamination directly in the ground without the need for excavation, significantly reducing the costs associated with soil removal and disposal. Over the long run, this can make air sparging a more cost-effective solution for soil and groundwater remediation.

Conclusion: The Future of Air Sparging

As we reach the end of our journey through the world of air sparging, it's time to look towards the future.

With advancements in technology, air sparging is continually improving. Innovations in system design, the development of more efficient air spargers, and sophisticated monitoring techniques all contribute to making air sparging more effective and efficient.

Future trends indicate an increased integration of air sparging with other remediation techniques. For instance, the combination of air sparging with bioremediation – using microorganisms to degrade contaminants – holds great promise for more sustainable and efficient remediation.

Finally, let's not forget the role that you and I can play in this. Understanding and advocating for technologies like air sparging is a step towards a cleaner and healthier environment. Let's continue to learn, explore, and do our part in preserving the world we live in.

In conclusion, air sparging, while a scientific and technical concept, is a critical tool in our environmental stewardship arsenal. It is a testament to human ingenuity, harnessing the simple power of air to clean our precious earth. Thank you for joining me on this enlightening journey into the depths of air sparging.

At this point, you're equipped with a broad understanding of air sparging, the critical role of air spargers, and their myriad applications. If you have further questions, need advice, or are considering implementing an air sparging system, our team at Hengko is here to assist.

With our expertise in air sparger system design and implementation, we can help you make the right choices for your specific project. Don't hesitate to reach out to us; we're eager to help you navigate the fascinating world of air sparging.

Send us an email at ka@hengko.com, and let's get the conversation started. We're looking forward to hearing from you soon!