How Does a Sparger Pipe Work? Gas Diffusion Principles Explained

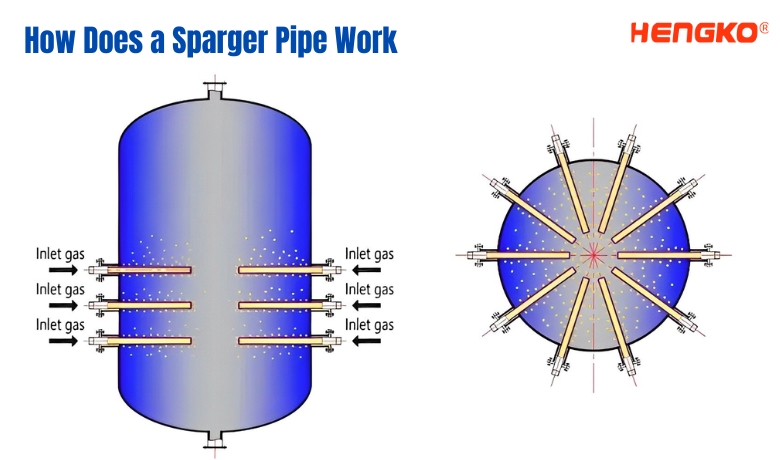

How Does a Sparger Pipe Work?

As we know, Gas diffusion plays a critical role in many industrial processes, including fermentation, chemical reactions,

wastewater treatment, and liquid mixing systems.

One of the most effective tools for achieving efficient gas–liquid contact is the sparger pipe.

But how does a sparger pipe actually work, and why is it so widely used in industrial applications?

In this article, we explain the working principle of a sparger pipe, focusing on gas diffusion mechanisms, micro-bubble formation,

and the engineering factors that determine performance.

What Is a Sparger Pipe?

Before introduce other details, Lets us to know what a sparger pipe really is ?

In shorter , A sparger pipe is a gas diffusion component designed to introduce gas into a liquid in the form of fine,

evenly distributed bubbles. Unlike filters, which are intended to remove particles, a sparger pipe is used to

disperse gas efficiently throughout a liquid phase.

Industrial sparger pipes are commonly manufactured from porous sintered metal, allowing gas to pass

through thousands of interconnected micro-pores.This structure enables stable and uniform bubble formation,

which significantly improves gas–liquid mass transfer efficiency.

If you are looking for detailed sparger information

— especially if you need a custom pipe sparger designed for your gas diffusion system

— you can explore our Sparger Pipe product page to see proven designs we have

delivered for previous projects.

Why Gas Diffusion Matters in Industrial Processes

One clear purpose. When gas is diffused efficiently, the process becomes more stable,

more effective, and far less expensive to run.

In systems where gas must dissolve, react, or transfer into a liquid, poor diffusion can lead to:

*Large bubbles with limited surface area

*Uneven gas distribution

*Low oxygen or gas utilization efficiency

*Increased energy consumption

From an engineering perspective, gas diffusion efficiency depends on three key factors:

1.Bubble size – Smaller bubbles provide greater surface area

2.Bubble residence time – Longer contact time improves dissolution

3.Uniform distribution – Prevents dead zones and concentration gradients

A properly designed sparger pipe addresses all three factors simultaneously.

How a Sparger Pipe Works:

Step-by-Step Gas Diffusion Process

Yes, now lets check the really spark pipe work process .

Step 1: Gas Enters the Sparger Pipe Under Controlled Pressure

Gas is introduced into the sparger pipe through an inlet connection, typically under controlled pressure.

The operating pressure must be sufficient to overcome the liquid head pressure and the inherent resistance

of the porous structure.

Stable inlet pressure ensures consistent gas flow and prevents irregular bubble formation.

Step 2: Gas Passes Through the Porous Structure

Inside a sintered sparger, gas flows through a three-dimensional porous metal network.

Unlike drilled holes, sintered pores are:

*Uniformly distributed

*Interconnected

*Precisely controlled in size

This porous structure acts as a flow regulator, evenly distributing gas across the entire surface of the sparger pipe.

Step 3: Formation of Micro Bubbles at the Pipe Surface

As gas exits the micro-pores, it forms fine bubbles at the liquid–solid interface. Bubble size is influenced by:

*Pore size and pore distribution

*Surface tension of the liquid

*Gas flow rate

Because the pores are consistent, bubble formation is stable and repeatable.

This is why sintered sparger pipes are often referred to as micro bubble diffusers or fine bubble spargers.

Step 4: Enhanced Gas–Liquid Mass Transfer

Once released, the micro bubbles rise slowly through the liquid, maximizing contact time. This significantly improves:

*Gas dissolution efficiency

*Reaction rates

*Oxygen transfer efficiency (OTE) in biological systems

Compared to large bubbles from drilled pipes, micro bubbles deliver higher mass transfer at lower gas consumption.

Sintered Sparger Pipe vs Drilled Pipe:

Key Differences in Gas Diffusion

| Feature | Sintered Sparger Pipe | Drilled Pipe |

|---|---|---|

| Bubble size | Fine & uniform | Large & uneven |

| Gas distribution | Even across surface | Localized outlets |

| Mass transfer efficiency | High | Low |

| Clogging risk | Low, cleanable | High |

| Service life | Long | Short |

In practical applications, sintered sparger pipes consistently outperform drilled pipes,

especially in processes that require stable and efficient gas diffusion.

3-Key Factors That Affect Sparger Pipe Performance

1. Pore Size and Bubble Size Relationship

Pore size directly determines the size of bubbles produced. Smaller pores generate finer bubbles,

increasing gas–liquid contact area.

Typical pore sizes range from a few microns to tens of microns, depending on the application.

2. Gas Flow Rate and Pressure Drop

As gas flow rate increases, bubble size and distribution may change. Proper sparger design balances:

*Desired gas throughput

*Acceptable pressure drop

*Bubble stability

Engineering-grade sparger pipes are designed to maintain performance across a defined operating range.

3. Material Selection

Material choice affects corrosion resistance, strength, and service life. Sintered stainless steel sparger pipes are widely used due to their:

*Excellent corrosion resistance

*Mechanical strength

*Thermal stability

*Long-term pore structure stability

Typical Applications of Sparger Pipes

Sparger pipes are used across a wide range of industries, including:

*Fermentation & bioreactors – Oxygen and gas supply for microbial growth

*Chemical processing – Gas–liquid reactions and mixing

*Wastewater treatment – Aeration and oxygen transfer

*Dissolution systems – Rapid gas or reagent dispersion

In each case, controlled gas diffusion is essential for process efficiency and consistency.

Why Sintered Stainless Steel Is Ideal for Sparger Pipes

Sintered stainless steel combines precision manufacturing with durability. Key advantages include:

*Stable pore structure over long service life

*Resistance to fouling and clogging

*Compatibility with cleaning and backflushing

*Suitability for high-pressure and high-temperature environments

These characteristics make sintered stainless steel the preferred material for demanding

industrial sparger applications.

Choosing the Right Sparger Pipe for Your Application

When selecting a sparger pipe, consider:

*Required gas flow rate

*Desired bubble size

*Operating pressure and temperature

*Chemical compatibility

For complex processes, custom sparger pipe solutions with tailored pore size, dimensions,

and connections provide the best performance.

FAQ About Sparger Pipe Working Principles

Q: Is a sparger pipe the same as a filter?

No. A sparger pipe is designed for gas diffusion, not particle filtration.

Q: What information should be defined before designing a sparger pipe system?

Before designing a sparger pipe system, it is essential to clearly define the process objectives and operating conditions.

Key parameters include the type of gas being introduced, the properties of the liquid (viscosity, surface tension, temperature),

target gas transfer efficiency, operating pressure, and available installation space.

From an engineering perspective, clearly defining these parameters at the beginning helps avoid common issues

such as oversized spargers, unstable bubble formation, or excessive pressure drop later in operation.

Q: What determines bubble size in a sparger pipe?

Primarily pore size, gas flow rate, and liquid properties.

Q: How do I determine the correct pore size for a sparger pipe?

Pore size selection is one of the most critical factors in sparger performance. Smaller pores generate finer bubbles,

which increase gas–liquid contact area and improve mass transfer efficiency.

However, smaller pores also result in higher pressure drop.

The optimal pore size is determined by balancing:

*Desired bubble size

*Available gas pressure

*Liquid properties

*Risk of fouling or clogging

In many industrial applications, testing or pilot-scale validation is recommended to confirm the ideal pore size range.

Q: Can sparger pipes clog over time?

Sintered metal sparger pipes are resistant to clogging and can often be cleaned or backflushed.

Q: Why is my sparger producing large or uneven bubbles?

Large or uneven bubbles are typically caused by one or more of the following factors:

*Excessive gas flow rate

*Inadequate inlet pressure control

*Non-uniform pore structure

*Partial blockage or fouling

In sparger pipe systems, uneven bubbles often indicate flow channeling or localized resistance differences.

Reducing flow rate, improving pressure regulation, or using a sintered sparger with uniform pore distribution

can significantly improve bubble consistency.

Q: What pressure is required to operate a sparger pipe?

Operating pressure depends on pore size, liquid depth, and gas flow requirements.

Q: How does sparger geometry affect gas diffusion efficiency?

The geometry of a sparger pipe—such as length, diameter, wall thickness, and pore distribution

—directly affects gas dispersion uniformity.

Longer spargers distribute gas over a wider area, while proper wall thickness ensures structural stability under pressure.

Uniform gas outlet distribution prevents localized high-velocity zones, which can lead to large bubbles

and inefficient mass transfer.

Q: How long does a sintered sparger pipe last?

With proper use and cleaning, service life can extend for many years.

Q: What causes pressure drop in sparger pipe systems?

Pressure drop across a sparger pipe is influenced by:

*Pore size and porosity

*Sparger length and wall thickness

*Gas flow rate

*Liquid back pressure

A well-designed sparger pipe balances sufficient resistance to ensure uniform gas distribution

while avoiding excessive pressure loss that increases operating costs.

Q: How do liquid properties affect sparger performance?

Liquid properties such as viscosity, density, and surface tension significantly influence bubble formation

and rise velocity. High-viscosity liquids typically require finer pore sizes or higher operating pressures

to achieve effective gas dispersion.

Temperature also affects gas solubility and bubble behavior, which must be considered during sparger system design.

Q: Can a sparger pipe become clogged during operation?

Yes, sparger pipes can become fouled over time, especially in liquids containing solids, biofilms, or precipitates.

However, sintered metal sparger pipes are more resistant to clogging due to their interconnected pore structure.

Many designs allow for cleaning by backflushing, chemical cleaning, or thermal treatment,

restoring performance without replacement.

Q: How do I design a sparger pipe for high-pressure applications?

High-pressure sparger systems require careful attention to:

*Mechanical strength of the sparger body

*Wall thickness and material selection

*Connection integrity

*Safety factors

Materials such as sintered stainless steel or high-strength alloys are commonly used to maintain structural

integrity while preserving diffusion performance under elevated pressures.

Q: How do I scale a sparger pipe system from lab to production scale?

Scaling up a sparger system is not simply a matter of increasing size. Gas flow distribution, pressure drop, and bubble dynamics change with scale.

Successful scale-up typically involves:

*Maintaining similar gas flux per unit area

*Adjusting sparger length or quantity

*Validating performance through pilot testing

Ignoring these factors can lead to reduced efficiency at larger scales.

Q: What materials are best suited for corrosive or aggressive environments?

Material selection depends on chemical compatibility with both the gas and liquid.

Stainless steel is commonly used due to its balance of corrosion resistance, strength, and cost.

For highly aggressive environments, specialty alloys or titanium may be required to ensure long-term reliability.

Q: When is a custom-designed sparger pipe necessary?

Custom sparger pipe designs are recommended when:

*Standard sizes do not fit available space

*Specific pore size distributions are required

*Operating pressures or temperatures exceed standard limits

*Unique process goals must be achieved

Custom solutions allow engineers to optimize gas diffusion performance for their exact application.

Q: How do modern manufacturing techniques improve sparger pipe quality?

Advanced manufacturing methods such as precision sintering, controlled pore forming, and process simulation

enable tighter control over pore size and structural consistency.

These advancements result in more predictable performance, longer service life, and improved reliability

in demanding applications.

Q: How can I evaluate whether my current sparger system is underperforming?

Signs of underperformance include:

*Reduced gas absorption efficiency

*Increased gas consumption

*Visible large bubbles or uneven dispersion

*Rising pressure drop over time

Regular inspection and performance monitoring help identify when a sparger system requires cleaning,

adjustment, or redesign.

Conclusion

A sparger pipe works by diffusing gas through a porous structure to generate fine, uniform bubbles that

enhance gas–liquid mass transfer.

Compared to conventional drilled pipes, sintered sparger pipes deliver superior diffusion efficiency, stability, and durability.

Understanding gas diffusion principles allows engineers to select and design gas sparger pipes that optimize performance,

reduce energy consumption, and improve process reliability.

Send your message to us: