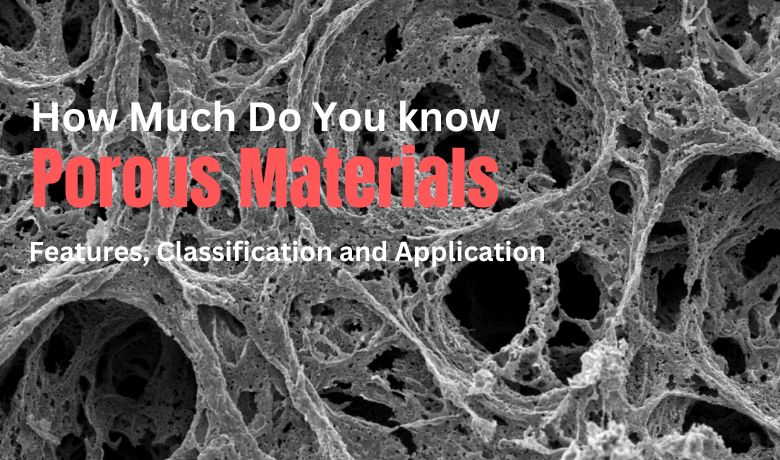

How Much Do You Know About Porous Material ?

Porous materials are everywhere, from the bone in your body to the filter in your coffee maker.

But how can something full of holes be so significant? The answer lies in the intricate dance between

the solid material itself and the vast network of pores within it. This interplay creates unique properties

that have revolutionized fields as diverse as medicine, energy storage, and even space exploration.

Imagine a material riddled with tiny pockets, invisible tunnels, and microscopic cavities. These aren't defects

– they're the defining characteristic of porous materials, and they hold the key to a surprising number of

advancements across various industries.

Have you ever wondered how astronauts breathe clean air on the International Space Station? Or how scientists

can create lighter, stronger building materials? The answer might surprise you – it all has to do with the remarkable

world of porous materials. Buckle up, and let's delve into the fascinating science behind these hole-y wonders!

What Are Porous Materials?

At their core, porous materials are simply materials riddled with pores – tiny spaces or voids within their structure.

These pores can vary dramatically in size, ranging from microscopic nanometers (billionths of a meter) to large

millimeter-sized cavities (thousandths of a meter). The size, shape, and how these pores are connected all play a

crucial role in determining a material's properties.

There are two main types of porosity to consider:

*Open-cell porosity:

Imagine a sponge. That's essentially open-cell porosity. The pores are interconnected, allowing fluids

to easily flow through them. Coffee filters, foams, and some types of bone are examples of open-cell materials.

*Closed-cell porosity:

Here, the pores are isolated bubbles within the solid material, not connected to each other. Think of a

pumice stone – full of holes, but the water can't travel between them. Polystyrene packing peanuts and

some volcanic rocks are examples of closed-cell materials.

By understanding the type and characteristics of a material's porosity, scientists and engineers can design

materials for specific applications. We'll explore how this is done in the next section!

Types of Porous Material

The world of porous materials is vast and encompasses a wide range of natural and synthetic materials.

Here's a glimpse into some of the most common types, classified based on their origin or composition:

Natural Porous Materials:

Rocks and Minerals:

Sandstone, pumice, and zeolites are some examples of naturally occurring porous rocks.

These materials find use in filtration, construction aggregates, and even cat litter due to

their varying pore sizes and surface areas.

Biological Materials:

Bone, wood, and cork are all natural porous materials with unique properties. Bone, for instance,

has a complex open-cell structure that provides strength and flexibility, while wood's porosity allows

for water and nutrient transport in plants.

Synthetic Porous Materials:

Polymers:

Polymeric foams like polyurethane and polystyrene are widely used for packaging, insulation,

and cushioning due to their closed-cell structure that traps air.

Ceramics:

These engineered materials can be designed with a controlled pore structure, making them ideal for

applications like filtration membranes, catalysts, and fuel cells.

Metals:

Porous metals are gaining traction in areas like lightweight construction materials and biomedical implants

due to their high strength-to-weight ratio and the ability to tailor their porosity for specific needs.

Metal-Organic Frameworks (MOFs):

These designer materials are synthetic marvels with a highly ordered and tunable pore structure.

They hold immense potential in gas storage, separations, and drug delivery.

These porous materials we mentioned just a sampling of the diverse world of porous materials.

Properties of Porous Materials

The unique combination of solid and void space in porous materials grants them a range of properties

that make them valuable across various applications. Let's delve into some of the key physical, mechanical,

and chemical properties of porous materials:

Physical Properties:

Density:

Due to the presence of pores, porous materials are generally less dense than their non-porous counterparts.

This makes them lightweight, which is crucial in applications like aerospace engineering and construction.

*Porosity Percentage:

This value represents the volume of voids within a material compared to its total volume. A higher percentage indicates a more open and interconnected pore structure.

*Permeability:

This property refers to a material's ability to allow fluids (gases or liquids) to pass through its pores. The pore size, shape, and connectivity significantly influence permeability.

Mechanical Properties:

*Strength:

The presence of pores can sometimes decrease a material's overall strength.

However, clever engineering of pore structure can create porous materials with

surprising strength-to-weight ratios, making them valuable in lightweight construction.

*Elasticity:

This property determines how much a material can deform under stress and return to

its original shape. Porosity can influence elasticity in complex ways, depending on the

material and pore structure.

Chemical Properties:

*Reactivity:

The high surface area created by pores can make them more reactive compared to non-porous materials.

This is advantageous in applications like catalysis, where increased surface area promotes chemical reactions.

*Resistance:

Porous materials can be tailored to resist specific elements or chemicals. For instance, some porous ceramics

exhibit excellent heat resistance, making them suitable for high-temperature applications.

By understanding this interplay of properties, scientists and engineers can design porous materials for

specific needs. In the next section, we'll see how these materials are put to work in various industries!

Benefits and Challenges of Porous Materials

Porous materials offer a unique set of advantages that make them valuable across various industries.

Here's a look at some of the key benefits:

*High surface area:

The intricate network of pores creates a large surface area within a small volume.

This is beneficial for processes like filtration, adsorption, and catalysis, where increased surface

area enhances interaction between the material and fluids/gases.

*Lightweight:

Due to the presence of pores, porous materials are generally lighter than their non-porous counterparts.

This is crucial in applications like aerospace engineering and fuel-efficient vehicles where weight reduction is a major goal.

*Controlled flow properties:

The size, shape, and connectivity of pores can be tailored to control how fluids flow through the material.

This enables precise filtration, controlled drug delivery, and efficient gas separation.

*Tailorable properties:

A wide range of materials can be made porous, and the pore structure itself can be engineered

to achieve specific properties. This versatility allows scientists to design materials for diverse applications.

However, porous materials also come with some challenges:

*Strength:

The presence of pores can decrease the overall strength of a material.

Mitigating this requires careful design and processing techniques.

*Fracture:

Pores can act as stress concentration points, making the material more susceptible

to cracking or fracture under high pressure.

*Manufacturing complexity:

Creating a desired pore structure can be complex and require specialized manufacturing

techniques, which can increase costs.

Special Uses of Sintered Stainless Steel Porous Materials

Sintered stainless steel porous materials are a specific type of porous material with unique advantages:

*High strength and durability:

Sintering, the manufacturing process, creates strong bonds between stainless steel particles,

resulting in a robust and long-lasting material.

*Corrosion resistance:

Stainless steel offers excellent resistance to corrosion, making these materials ideal for

harsh environments or applications involving fluids.

*Biocompatibility: Certain grades of stainless steel are biocompatible, meaning they can be safely implanted

in the human body. This opens doors for biomedical applications like filters or bone implants.

*Tailorable pore structure:

The size and distribution of pores in sintered stainless steel can be controlled, allowing for precise filtration or fluid distribution.

These properties make sintered stainless steel porous materials valuable in various applications, including:

*Filtration:

They are widely used in industrial filters for liquids and gases, especially in applications requiring high strength and durability.

*Fluid distribution:

Their controlled porosity allows for even distribution of fluids in processes like chromatography or fuel cells.

The intricate pore structure can effectively dampen sound waves, making them useful in noise reduction applications.

*Biomedical implants:

The biocompatible nature of certain grades makes them suitable for bone implants or drug delivery devices.

The combination of high strength, corrosion resistance, and a tunable pore structure makes sintered stainless steel porous materials a valuable asset in various demanding applications.

Applications of Porous Materials: A World of Holes in Action

The unique properties of porous materials have led to a vast array of applications across various sectors.

Here's a glimpse into how these hole-y wonders are put to work:

Industrial Applications:

Filtration Systems:

From coffee filters to massive industrial filters, porous materials are essential for separating desired

components from a mixture. Their controlled pore size allows them to trap unwanted particles while

letting the desired fluid pass through.

Catalyst Supports:

In chemical reactions, catalysts accelerate the process. Porous materials with high surface area provide

a platform for these catalysts, maximizing their efficiency in various industrial processes.

Everyday Uses:

Insulation:

The trapped air within the pores of materials like fiberglass or foam acts as a great insulator,

keeping our homes warm in winter and cool in summer.

Sound Absorption:

Porous materials like acoustic panels or soundproofing foams have the ability to

absorb sound waves, dampening noise and creating a quieter environment.

Acoustic panel

Cutting-Edge Applications:

Biomedical Engineering:

Porous materials are revolutionizing this field. For instance, porous scaffolds are used for

tissue engineering, providing a structure for new cells to grow on, and porous drug delivery

systems can release medication in a controlled manner.

Aerospace:

The need for lightweight yet strong materials is crucial in aerospace engineering.

Porous metals are being explored for their potential to create lighter aircraft parts

without compromising strength.

These are just a few examples – the applications of porous materials are truly diverse and

constantly evolving. As scientists continue to develop new and innovative materials with

controlled pore structures, the possibilities for their use will undoubtedly continue to expand!

Conclusion

As we've explored throughout this blog, porous materials are not just fascinating from a scientific

perspective but also incredibly versatile and essential across a broad spectrum of industries.

From the natural sponginess of organic materials like wood and bone to the highly engineered porosity

in ceramics and metals, these materials play critical roles in everyday products and cutting-edge

technologies alike.

Let's continue to explore and innovate with porous materials, unlocking new solutions and

possibilities that can transform our world. Especial Porous Sintered stainless steel filter, if

Interested to know more details , please feel free to contact HENGKO by email

ka@hengko.com or as following form.

Send your message to us: