Why Passivation is Crucial for Maintaining Stainless Steel’s Performance

Stainless steel is an incredible material that plays a pivotal role in various industries, thanks to its unique characteristics and unmatched performance. But did you know that there's a hidden secret to maintaining its performance and longevity? This secret lies in a process known as passivation.

Introduction to Stainless Steel

Understanding the power of passivation begins with appreciating the fundamentals of stainless steel itself. Stainless steel is not just a simple material;

it's an alloy made from iron, carbon, and a generous dose of chromium.

What Makes Stainless Steel Unique

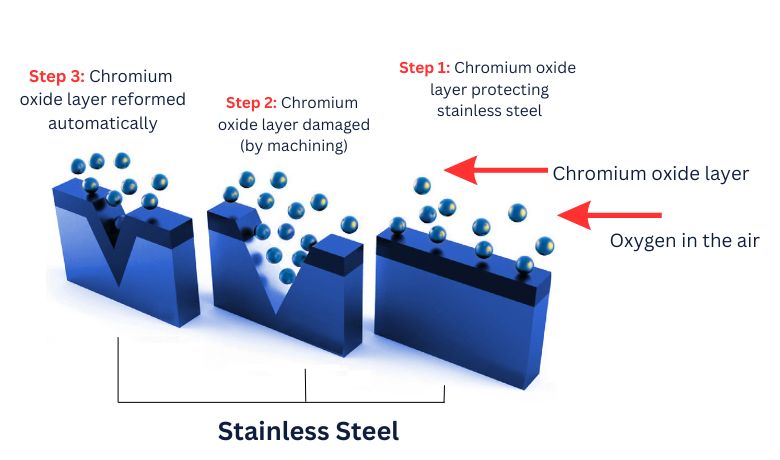

The key player in the stainless steel story is chromium. When exposed to oxygen, chromium forms a thin, invisible layer of chromium

oxide on the surface of the steel. This layer is passive, meaning it doesn't react with anything else.

1. Understanding the Corrosion Resistance

Chromium oxide is the guardian angel of stainless steel. It prevents rust and corrosion, which are common pitfalls of most other metals.

This corrosion resistance gives stainless steel its name and its widespread use.

2. The Role of Passivation in Stainless Steel

Now, let's dive into the main topic - passivation. Passivation is a chemical process that enhances the naturally occurring chromium oxide layer.

This makes the steel even more resistant to rust and corrosion.

3. The Science Behind Passivation

During passivation, the stainless steel is treated with a mild acid solution. This removes free iron and other contaminants from the surface,

which could potentially disrupt the formation of the chromium oxide layer.

Would you like to know why stainless steel need to passivate?

At first, we need to know what is the meaning of the passivation-stainless steel? The passivation of stainless steel refers to make the surface of stainless steel react with a passivation agent to form a stable passivation film which protects the stainless steel substrate from rusting caused by oxidation and corrosion. The rust resistance performance of stainless steel is relatively good. However, in coastal areas or in contact with some acid and alkali chemicals, the generated chloride ions can easily penetrate the passive film of stainless steel. Stainless steel will gradually corrode and rust over time. Therefore, stainless steel needs to be passivated. Passivated stainless steel can improve the original anti-rust foundation by 3-8 years, greatly reducing the chance of stainless steel rust.

HENGKO stainless steel sintered filter element has precise air pore size, uniform filter hole size and uniform distribution; good air permeability, fast circulation, good interception effect, high filtration efficiency; good corrosion resistance, high-temperature resistance, heat shock resistance, stainless steel material can be 600 Operation at high temperature; the length of the fine filter tube can reach 800mm, the maximum size of the filter plate structure can reach 800mm long * 450mm wide, and the maximum diameter of the round filter structure can reach 450mm. We also provide the passivation of product parts, If you need to apply to the stricter corrosion resistance and rust resistance environment.

Benefits of Passivation

There are numerous benefits to passivating stainless steel, all of which contribute to its enhanced performance and longevity.

How to do the passivation-stainless steel? Let us tell you.

Because different types of stainless steel use different combinations of passivation chemicals, some details will be different during the passivation process of stainless steel. Passivation needs to custom. However, the basic process often has the same steps: Ensure that the surface of the part is clean. Only when the substrate is exposed can it be better passivated. Put one or several parts to be passivated into a container. Pour the chemical liquid into the container and let the parts soak for a period of time. Wash with running water. Ensure the surface of the part cleaned and without residual passivation liquid on.

Nitric acid passivation is one of the current basic passivation technologies. Before choosing the passivation technology, we need to know the chemical solution required for the passivation reaction of stainless steel to avoid using the wrong solution to cause damage to parts. And the same time choosing the related passivation technology according to the characteristic of different stainless steel. For example, the chromium content of austenitic stainless steel (such as 304 stainless steel) is often higher than that of martensitic stainless steel (such as 430 stainless steel), making austenitic alloys more resistant to corrosion and pitting.

Before passivation of stainless steel parts, the following points should be considered:

Weldments may not be suitable for passivation. The passive film on the surface of stainless steel makes it corrosion resistant. Arc welding will subject the material to a short period of high temperature thermal cycling, thereby destroying its corrosion resistance.

A custom chemical bath is required. The temperature and type of acid used in the passivation process must be adjusted according to the alloy being passivated. This adds cost and complexity compared to electropolishing. Some alloys cannot be passivated. For example, some stainless steel alloys with low chromium and nickel content will be destroyed. Therefore, they cannot be passivated.

The main advantage of stainless steel passivation is that it can improve the rust resistance of stainless steel parts, and the cost is lower than that of electropolishing. The biggest disadvantage of the electropolishing process is that it is more expensive than the standard passivation process. In addition, electropolishing does not have a significant effect on the protective oxide layer of steel like passivation.

However, when talking about the surface condition of parts into the main consideration, electropolishing still is the preferred treatment. Passivation is not like electropolishing to make the surface of the part smooth, it also does not greatly change the appearance of the part. Therefore, the passivation is not an ideal method if the product needs a smooth and non-stick surface. The food and pharmaceutical industries tend to use electro-polished stainless steel surfaces because the surface is smooth and easy to clean and disinfect.

FAQs

1. What is passivation?

Passivation is a chemical process that enhances the naturally occurring chromium oxide layer

on stainless steel, thereby increasing its resistance to rust and corrosion.

2. How does passivation work?

During passivation, the stainless steel is treated with a mild acid solution to remove

surface contaminants. It's then rinsed and dried, and the chromium reacts with air to form a new, strengthened chromium oxide layer.

3. Why is passivation important for stainless steel?

Passivation is important for stainless steel as it increases the material's corrosion resistance, prolongs its lifespan,

and maintains its aesthetic appeal.

4. How often should stainless steel be passivated?

The frequency of passivation depends on the operating conditions of the stainless steel item. In more corrosive

environments or where the item is frequently handled, more regular passivation may be necessary.

5. Does passivation affect the appearance of stainless steel?

Yes, passivation helps to maintain the shiny, clean appearance of stainless steel by preventing rust and corrosion.

6. Can all stainless steel items be passivated?

Yes, all stainless steel items can be passivated. However, the need for passivation will depend on the

operating conditions of the item.

7. Is passivation a costly process?

While there are costs involved in passivation, it is generally considered cost-effective given the protection

it provides to the stainless steel and the resultant extension of its lifespan.

8. What happens if stainless steel is not passivated?

If stainless steel is not passivated, it may be more susceptible to corrosion, which could result in a shorter

lifespan and diminished aesthetic appeal.

9. Does passivation make stainless steel stronger?

Passivation doesn't necessarily make stainless steel stronger. It improves its durability by enhancing its resistance to corrosion.

10. Can I perform passivation at home?

Passivation should be performed by trained professionals to ensure the process is conducted correctly and safely.

Need More Details? We're Here to Help!

Understanding the intricacies of sintered stainless steel and the passivation process can be overwhelming.

If you're interested in enhancing the performance and lifespan of your stainless steel components or seeking the ideal

OEM special sintered metal filter for your filtration system, our team is here to guide you.

Get in touch with us at HENGKO, and let's unlock the full potential of your systems together. Reach out to us via email

at ka@hengko.com, and our knowledgeable team will be more than happy to assist you with your queries.

Your path to an optimised filtration system is just an email away. Don't wait. Contact us today!