Types of Sparger All You Interested to Know

If you're in the gas or purification industry, you're likely familiar with spargers or the gas diffusion process.

Today, let's take a closer look at spargers – those simple yet essential devices that are crucial in many industrial applications.

And if you're not familiar with spargers, don't worry! Let’s break it down step by step.

What are spargers?

In essence, spargers are like tiny showerheads for gas. They introduce gas, typically air or oxygen, into liquids in a controlled manner.

The key lies in their ability to disperse the gas into small bubbles, maximizing the surface area for efficient contact with the liquid.

Why are spargers so important?

This seemingly simple function of creating bubbles has a profound impact across various industries.

Here's a glimpse of why spargers are essential:

*Biotechnology:

Spargers are the silent workhorses in fermentation processes, ensuring proper oxygen supply for

microorganisms to produce things like biofuels, enzymes, and pharmaceuticals.

*Wastewater treatment:

Efficiently breaking down pollutants often relies on good aeration. Spargers play a crucial role in introducing

oxygen-rich bubbles to promote the growth of beneficial bacteria that clean the wastewater.

*Chemical processing:

Many chemical reactions require precise control of gas introduction and mixing.

Spargers provide the means to achieve this by creating a uniform dispersion of gas throughout the liquid reaction mixture.

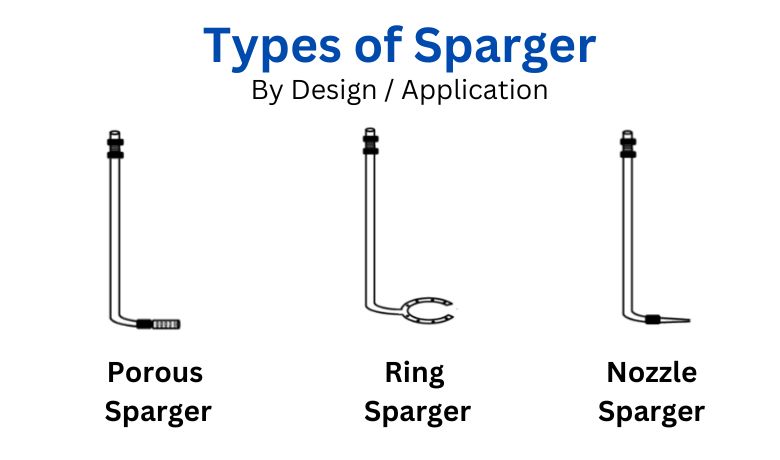

Then Because there are many types of sparger used in different industry, so for us , we should know all details

each spargers, like features, advantage, why choose them , then we can make a right decisions for your project

with better and perfect result. so let's check details each types of sparger now.

1. Porous Metal Spargers

While the exact origin is unclear, porous metal spargers have likely been around since the early days of industrial

gas-liquid mixing. Their development stemmed from the need for a more efficient and reliable way to introduce

gas into liquids.

Early iterations might have involved perforated plates or simple tubes, but these lacked the precision and control

offered by porous metal.

The development of sintering techniques, which involve bonding metal particles at high temperatures without

melting them, revolutionized sparger design. This process allowed for the creation of a uniform network of pores

throughout the metal, enabling the controlled creation of tiny bubbles for optimal gas-liquid contact.

Built to Last: Key Features of Porous Metal Spargers

*Uniform Pore Distribution:

The sintering process ensures a consistent pore size throughout the metal, leading to the formation of uniform gas bubbles for efficient mass transfer.

*High Durability:

Porous metal is incredibly strong and can withstand high pressures and harsh operating environments, making it ideal for demanding industrial applications.

*Corrosion Resistance:

Depending on the chosen metal, porous spargers can resist corrosion from various chemicals and liquids, ensuring long service life.

Unmatched Performance: Advantages of Porous Metal Spargers

*Efficient Gas-Liquid Distribution:

The uniform pores create a multitude of tiny bubbles, maximizing the surface area for gas-liquid contact and promoting efficient mass transfer.

*Long Lifespan:

The robust construction and corrosion resistance of porous metal translate to a long lifespan, minimizing replacement costs and downtime.

*Easy Maintenance:

Porous metal spargers are generally easy to clean and maintain, ensuring consistent performance over time.

Choosing the Right Tool: When to Opt for Porous Metal Spargers

Porous metal spargers excel in various applications, but some key factors make them the ideal choice:

*High-Pressure Environments:

Their robust build allows them to handle high operating pressures without compromising performance.

*Aggressive Environments:

Many metals used in porous spargers offer excellent resistance to corrosion from harsh chemicals and liquids.

*Uniform Gas Distribution:

The even pore distribution ensures consistent bubble size and uniform gas dispersion throughout the liquid.

Price Range: Tailored to Your Needs

The cost of a porous metal sparger can vary depending on several factors, including size, level of customization,

and desired material. Generally, expect a range of $200 to $$1000.

Customization is King: Tailoring Porous Metal Spargers

One of the biggest advantages of porous metal spargers is their high level of customization. Here's how you can tailor them to your specific needs:

*Pore Size:

The size of the pores directly affects the bubble size. Smaller pores create finer bubbles, ideal for applications requiring high mass transfer rates.

*Shape:

Porous metal spargers can be fabricated in various shapes, such as discs, tubes, or plates, to fit different tank geometries and applications.

*Material:

The chosen metal should be compatible with the operating environment and the gas/liquid being used. Common options include stainless steel, Hastelloy, and titanium.

Reliable Suppliers: Where to Find High-Quality Porous Metal Spargers

Several reputable manufacturers offer high-quality porous metal spargers. Here are a few trusted names:

*Mott Corporation

*Porvair Filtration Group

*Sintered Metal Filters

*GKN Sinter Metals

By considering these factors and consulting with a qualified supplier, you can select the ideal

porous metal sparger to optimize your gas-liquid mixing process.

2. Ceramic Spargers

The use of ceramics for filtration dates back centuries, with ancient civilizations employing them to purify water and other liquids.

This rich history of ceramic's effectiveness in separating materials paved the way for their application in sparging technology.

Early ceramic spargers were likely adaptations of existing filtration elements.

However, advancements in material science and manufacturing techniques have led to the development of highly

specialized ceramic spargers with exceptional properties.

One key innovation involved the development of precise control over pore size and distribution within the ceramic material.

This fine-tuning allows for the creation of spargers that generate bubbles of specific sizes, crucial for optimizing gas-liquid

mass transfer in various processes.

Built to Withstand the Heat: Key Features of Ceramic Spargers

*High Thermal Stability: Ceramic materials can withstand extremely high temperatures, making them ideal for applications involving hot liquids or high-temperature reactions.

*Chemical Resistance: Most ceramics are inert to a wide range of chemicals, allowing them to function effectively in environments with aggressive chemicals.

*Fine Pore Structure: Ceramic spargers can be engineered with a very fine pore structure, enabling the creation of tiny bubbles for efficient gas-liquid contact.

Champions in Harsh Environments: Advantages of Ceramic Spargers

*Suitable for High-Temperature Applications:

Their exceptional thermal stability allows them to function flawlessly in processes involving hot liquids or high-temperature reactions, where other materials might fail.

*Inert to Most Chemicals:

The chemical resistance of ceramics makes them the preferred choice for sparging in applications involving harsh chemicals that could corrode other materials.

*Efficient Mass Transfer:

The fine-tuned pore structure facilitates the formation of tiny bubbles, maximizing the surface area for gas-liquid contact and promoting efficient mass transfer.

When the Going Gets Tough: Choosing Ceramic Spargers

Ceramic spargers shine in specific situations where other materials might struggle:

*Aggressive Chemicals:

Their chemical resistance makes them ideal for use with harsh chemicals that could damage other types of spargers.

*High Temperatures:

When dealing with hot liquids or high-temperature reactions, the thermal stability of ceramics ensures reliable performance.

Investing in Performance: Price Range of Ceramic Spargers

The cost of a ceramic sparger can vary depending on several factors, including size, level of customization, and desired pore size. Generally, expect a range of $150 to $800.

Tailoring to Your Needs: Customization Options for Ceramic Spargers

Similar to porous metal spargers, ceramic spargers offer some degree of customization:

*Pore Size:

The pore size can be precisely controlled to generate bubbles of a specific size, optimizing gas-liquid contact for your unique application.

*Shape:

Ceramic spargers can be fabricated in various shapes, such as discs, tubes, or plates, to fit different tank geometries and applications.

Reliable Sources: Where to Find High-Quality Ceramic Spargers

Several reputable manufacturers offer high-quality ceramic spargers. Here are a few trusted names:

- Saint-Gobain

- CoorsTek

- Applied Porous Technologies

- Industrial Ceramics

- CeramTec

By considering these factors and consulting with a qualified supplier, you can select the ideal ceramic sparger to meet the specific demands of your high-temperature or chemically harsh application.

3. Plastic Spargers

Plastic's versatility extends far beyond packaging and consumer goods. In the realm of sparging, plastics have emerged as a cost-effective and practical solution for a wide range of applications.

The development of plastic spargers coincided with the advancements in polymer science throughout the 20th century. Early iterations might have used rudimentary techniques like drilled holes in plastic sheets. However, the advent of new plastics with specific properties and improved molding techniques paved the way for more sophisticated and efficient plastic sparger designs.

Today, a variety of plastics are used in sparger construction, each offering unique advantages depending on the application.

Lightweight Champions: Key Features of Plastic Spargers

*Lightweight:

Plastic's inherent lightness makes them easy to handle and integrate into existing systems.

*Cost-Effective:

Compared to metal and ceramic spargers, plastics offer a significant price advantage, making them ideal for budget-conscious applications.

*Easy to Mold:

Plastics offer great design flexibility, allowing for the creation of spargers in various shapes and configurations to suit specific needs.

Balancing Budget with Performance: Advantages of Plastic Spargers

*Economical:

The low cost of plastic makes them a budget-friendly option for applications where performance requirements are not as stringent.

*Suitable for Low-Pressure and Non-Aggressive Environments:

In low-pressure applications and environments free of harsh chemicals, plastic spargers can function effectively.

*Variety of Options:

The availability of different plastic types allows for selection based on specific chemical compatibility needs within a budget.

Choosing Wisely: When to Opt for Plastic Spargers

While plastic spargers offer numerous advantages, their limitations need to be considered:

*Pressure Limitations:

Plastic spargers may not be suitable for high-pressure applications due to potential structural weaknesses.

*Chemical Compatibility:

Certain chemicals can degrade or damage plastics. Careful selection based on chemical compatibility is crucial.

*Limited Customization:

Compared to metal and ceramic options, customization possibilities for plastic spargers are generally lower.

A Budget-Conscious Choice: Price Range of Plastic Spargers

The cost of a plastic sparger can vary depending on several factors, including size, complexity, and the type of plastic used. Generally, expect a range of $50 to $300.

Finding the Right Fit: Suppliers of Plastic Spargers

Several reputable manufacturers offer a variety of plastic sparger options. Here are a few trusted names:

- Entegris

- Parker Hannifin

- Porous Plastics

- SMC Corporation

- Porex Corporation

By carefully considering the application requirements and limitations of plastic spargers, you can leverage their cost-effectiveness and design flexibility to optimize your gas-liquid mixing processes within a budget.

4. Stainless Steel Spargers

A Time-Tested Material: The Enduring Legacy of Stainless Steel Spargers

Stainless steel boasts a long and illustrious history in industrial applications. Its inherent strength, corrosion resistance,

and thermal stability make it a natural choice for sparger construction.

The use of stainless steel spargers likely emerged alongside the development of industrial-grade stainless steel itself in the early 20th century.

Their durability and resistance to corrosion made them a valuable asset in various industries, from chemical processing to food and beverage production.

Over time, advancements in metalworking techniques and sintering processes have allowed for the creation of increasingly

sophisticated stainless steel spargers. Today, these spargers offer a high degree of customization and can be precisely tailored

to meet the specific needs of a wide range of applications.

Strength and Stability: Key Features of Stainless Steel Spargers

*High Strength:

Stainless steel's robust nature allows these spargers to withstand high operating pressures and demanding environments.

*Corrosion Resistance:

Stainless steel's resistance to corrosion from various chemicals makes them suitable for diverse applications.

*Thermal Stability:

These spargers can function effectively in processes involving hot liquids or moderate temperature variations.

A Material for All Seasons: Advantages of Stainless Steel Spargers

*Suitable for a Wide Range of Applications:

The versatility of stainless steel makes these spargers ideal for various industries, from food and beverage production to pharmaceuticals

and harsh chemical environments (depending on the specific grade of stainless steel).

*High Cleanliness Standards:

Stainless steel's smooth surface finish minimizes the risk of contamination, making it a preferred choice for applications with strict hygiene requirements.

*Durability and Long Lifespan:

The strength and corrosion resistance of stainless steel translate to a long service life, minimizing replacement costs and downtime.

Choosing the Right Steel for the Job: When to Use Stainless Steel Spargers

Due to their well-rounded properties, stainless steel spargers are a great choice for many applications:

*Environments Requiring High Cleanliness:

The smooth, non-porous surface of stainless steel minimizes the risk of harboring bacteria or contaminants, making it ideal for sterile environments.

*Applications with Corrosive Chemicals:

Depending on the specific grade of stainless steel, these spargers can withstand exposure to a wide range of chemicals, ensuring reliable performance.

*Need for Long Lifespan:

The durability of stainless steel makes these spargers a cost-effective choice in the long run, as they require minimal replacements.

Investing in Quality: Price Range of Stainless Steel Spargers

The cost of a stainless steel sparger can vary depending on several factors, including size, level of customization, and the specific grade of stainless steel used. Generally, expect a range of $100 to $700.

Trusted Sources: Suppliers of High-Quality Stainless Steel Spargers

Several reputable manufacturers offer high-quality stainless steel spargers. Here are a few trusted names:

- Pall Corporation

- Advantec MFS

- Mott Corporation

- Sinterflo

- Allegheny Bradford Corporation

By considering your specific application requirements and leveraging the versatility and durability of

stainless steel spargers, you can ensure optimal gas-liquid mixing performance for years to come.

5. Glass Spargers

A Clear Choice: The Role of Glass in Sparging

Glass, with its unique properties, has found its place in both laboratory and industrial sparging applications.

The use of glass spargers likely began in laboratory settings, where their transparency allowed for visual observation

of gas bubble formation and behavior within the liquid. As understanding of sparger design and function grew, glass spargers

were adapted for specific industrial applications requiring high chemical purity and inertness.

Today, glass spargers are a valuable tool for researchers and industrial processors alike,

offering a unique combination of visibility and chemical compatibility.

Transparent Champions: Key Features of Glass Spargers

*Chemical Inertness:

Glass is exceptionally inert to many chemicals, minimizing the risk of contamination or unwanted reactions.

*Transparency:

The ability to see through glass allows for real-time visual monitoring of bubble formation and behavior within the liquid.

*Fine Bubble Generation:

Glass spargers can be crafted to generate very fine bubbles, ideal for applications requiring high mass transfer rates.

A Window into the Process: Advantages of Glass Spargers

*Ideal for Visual Inspection Applications:

The transparency of glass allows for visual observation of gas dispersion and bubble behavior, aiding in process optimization and troubleshooting.

*Laboratory Use:

Glass spargers are widely used in laboratories due to their chemical inertness, visibility, and ease of cleaning.

*High Purity Applications:

For processes requiring exceptionally pure environments, glass spargers minimize the risk of contamination due to their inert nature.

Choosing the Right Glass for the Job: When to Use Glass Spargers

Due to their specific properties, glass spargers are best suited for certain applications:

*Applications Requiring High Purity:

The chemical inertness of glass makes them ideal for processes where maintaining the purity of the liquid is paramount.

*Visual Monitoring:

In applications where observing bubble behavior is crucial for process optimization, the transparency of glass spargers offers a significant advantage.

*Laboratory Settings:

Glass spargers are a mainstay in laboratories due to their versatility, ease of use, and ability to withstand common laboratory chemicals.

A Clear Investment: Price Range of Glass Spargers

The cost of a glass sparger can vary depending on several factors, including size, complexity, and the type of glass used (e.g., borosilicate glass). Generally, expect a range of $80 to $500.

Trusted Suppliers of Glass Spargers

Several reputable manufacturers offer high-quality glass spargers. Here are a few trusted names:

- Ace Glass Incorporated

- Chemglass Life Sciences

- Kontes Glass Company

- Wilmad-LabGlass

- Pyrex

Types of 5-Sparger Comparison

| Feature | Porous Metal | Ceramic | Plastic | Stainless Steel | Glass |

|---|---|---|---|---|---|

| History | Early development, advancements in sintering | Adapted from filtration, advancements in material science | Development alongside polymer science | Long history in industrial applications | Laboratory and industrial use |

| Key Features | Uniform pore distribution, high durability, corrosion resistance | High thermal stability, chemical resistance, fine pore structure | Lightweight, cost-effective, easy to mold | High strength, corrosion resistance, thermal stability | Chemical inertness, transparency, fine bubble generation |

| Advantages | Efficient gas-liquid distribution, long lifespan, easy maintenance | Suitable for high-temperature applications, inert to most chemicals, efficient mass transfer | Economical, suitable for low-pressure & non-aggressive environments | Suitable for wide range of applications, high cleanliness standards, durability | Ideal for visual inspection applications, laboratory use, high purity applications |

| Choosing Conditions | High-pressure environments, aggressive environments, uniform gas distribution | High-temperature applications, aggressive chemicals | Budget-sensitive applications, compatible chemicals | Environments requiring high cleanliness, corrosion resistance | High purity applications, visual monitoring |

| Price Range | $200 - $1000 | $150 - $800 | $50 - $300 | $100 - $700 | $80 - $500 |

| Customization | Highly customizable (pore size, shape, material) | Customizable (pore size, shape) | Limited customization | Highly customizable (design, pore size, shape) | Moderate customization options |

| Examples of Applications | Fermentation, wastewater treatment, chemical processing | High-temperature reactors, harsh chemical environments | Low-pressure aeration, non-critical mixing | Food & beverage production, pharmaceuticals, chemical processing | Laboratories, processes requiring high purity |

Choosing the Right Sparger Idea

Selecting the ideal sparger for your application requires careful consideration of various factors. Here's a breakdown of key elements to ensure you make the most informed decision:

1. Application Requirements: This is the foundation for your selection process. Analyze the specific demands of your application by considering:

*Pressure:

*Chemical Compatibility:

*Budget:

2. Industry Standards:

Certain industries have specific regulations or standards regarding sparger materials and performance.

Familiarize yourself with any relevant standards and ensure your chosen sparger complies with them.

This is especially crucial in industries like food and beverage production or pharmaceuticals.

3. Supplier Reputation:

Selecting a reliable supplier is essential. Research potential suppliers by considering:

*Experience:

*Customization Capabilities:

4. Future Needs:

Consider the long-term implications of your choice. Here are some questions to ponder:

*Scalability:

By thoroughly evaluating these factors, you'll be well-equipped to select the optimal sparger that delivers efficient gas-liquid mixing, meets industry standards, and aligns with your budgetary and future operational needs.

Conclusion

We've delved into the unique characteristics of five prominent types:

*Porous Metal Spargers:

*Plastic Spargers:

*Stainless Steel Spargers:

*Glass Spargers:

Choosing Your Perfect Sparger: A Tailored Solution

The ideal sparger selection hinges on understanding your specific needs. By carefully considering the following factors, you can ensure optimal gas-liquid mixing performance:

*Application Requirements:

*Supplier Reputation:

*Future Needs:

So the perfect sparger is a marriage of material properties, design features, and compatibility with your specific application.

Contact Us

HENGKO specialize in providing top-quality porous metal spargers tailored to meet your specific needs.

Whether you require a unique design, specific pore size, or material customization, our expert team is here to assist you.

Contact us today to discuss your requirements and let us help you create the perfect sparger for your application.

Reach out to us at ka@hengko.com for a consultation and personalized recommendations.

Don't miss the opportunity to enhance your system's performance with a custom-designed porous metal sparger from HENGKO!