What is a Sparger in Bioreactor All You Want To Know

What is a Sparger in Bioreactor?

In Short, Bioreactors are essential tools for industrial and research processes that involve the cultivation of microorganisms and cells. One key aspect of bioreactor design is the sparger, which plays a critical role in providing oxygen and mixing the contents of the bioreactor. In this blog post, we'll explore what a sparger is, its importance in bioreactors, and the challenges and solutions associated with sparger design and maintenance.

What is a Sparger ?

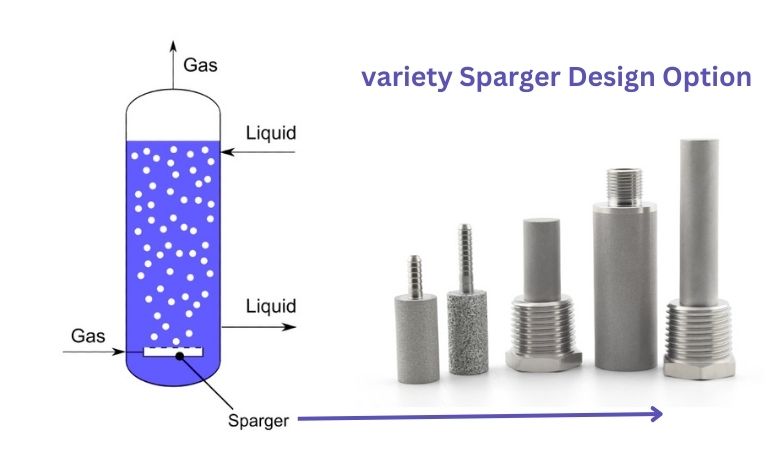

A sparger is a device used to introduce gas, typically oxygen, into a liquid medium in a bioreactor. The sparger is located at the bottom of the bioreactor and typically consists of a porous or non-porous material that allows gas to flow through it. Spargers come in a variety of designs, including disc spargers, ring spargers, and custom-designed spargers.

Importance of Spargers in Bioreactors

Spargers play two crucial roles in bioreactors: oxygen transfer and mixing.

Oxygen Transfer

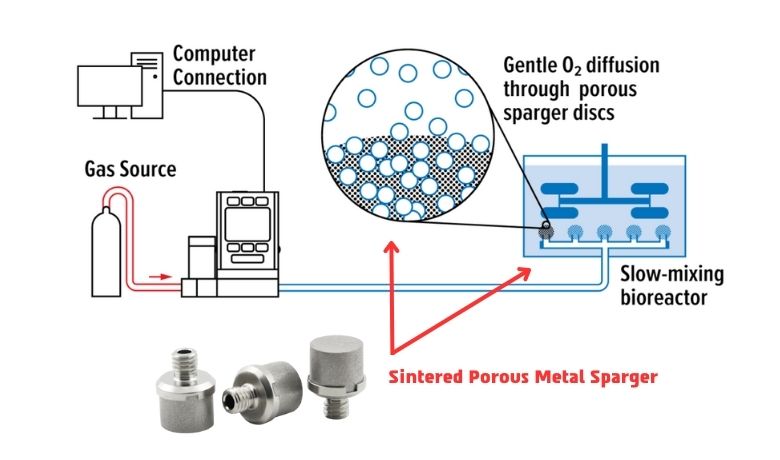

In bioreactors, the availability of oxygen is essential for the growth and metabolism of microorganisms and cells. Spargers aid in the transfer of oxygen from the gas phase to the liquid phase in the bioreactor. The efficiency of oxygen transfer depends on factors such as the gas flow rate and pressure, the type of sparger, and the vessel geometry.

Mixing

Uniform mixing of the contents of a bioreactor is essential for optimal growth and productivity of microorganisms and cells. Spargers aid in mixing by creating a stream of gas bubbles that rise to the surface and agitate the liquid contents of the bioreactor.

Sparger Design and Selection

Choosing the right sparger design and size is critical for the efficient operation of a bioreactor. The factors that influence the selection of a sparger include the type of bioreactor, gas flow rate and pressure, vessel geometry, and process requirements.

Types of Sparger Designs

Porous spargers are made of materials such as sintered metal, ceramic, or polymer, which allow gas to flow through the material. Non-porous spargers, on the other hand, are made of materials such as stainless steel and have holes or slots to allow gas to flow through. Custom-designed spargers can be tailored to specific bioreactor configurations and process requirements.

Challenges and Solutions with Spargers in Bioreactors

Several challenges are associated with spargers in bioreactors, including fouling, pressure drop, and inefficiency. Proper sparger design, regular cleaning, and maintenance can help overcome these challenges.

Fouling

Fouling occurs when the sparger becomes clogged with microorganisms or other particles, which reduces its efficiency. Regular cleaning and maintenance can help prevent fouling and prolong the life of the sparger.

Pressure Drop

A pressure drop can occur when gas flow through the sparger is restricted, which reduces the efficiency of oxygen transfer and mixing. The pressure drop can be minimized by selecting the right sparger design and size for the bioreactor configuration.

Inefficiency

Inefficiency occurs when the sparger is not delivering enough oxygen or creating enough mixing to meet process requirements. Inefficiency can be addressed by optimizing the sparger design and process conditions.

Applications of Spargers in Bioreactors

Spargers are used in a variety of industrial and research applications, including:

Industrial Applications

1. Pharmaceutical production:

Spargers are used in the production of drugs, vaccines, and other biological products. Bioremediation: Spargers are used to aerate contaminated water and soil, which promotes the growth of microorganisms that break down pollutants.

2. Wastewater treatment:

Spargers are used in the treatment of wastewater to promote the growth of microorganisms that consume organic matter and pollutants.

3. Food and beverage production:

Spargers are used in the production of beer, wine, and other fermented foods and beverages.

Research Applications

1. Cell culture: Spargers are used to provide oxygen and mixing in cell culture systems, which are used to grow and study cells.

2. Microbial fermentation: Spargers are used in microbial fermentation systems to promote the growth and metabolism of microorganisms.

FAQ about the Sparger in Bioreactor ?

1. What is a sparger in a bioreactor?

A sparger is a device that is used to introduce gases, such as air or oxygen, into a bioreactor. The sparger is typically located at the bottom of the bioreactor and consists of a porous material through which the gas is passed.

2. Why is a sparger used in bioreactors?

Spargers are used in bioreactors to provide oxygen to the microorganisms or cells being grown. Oxygen is necessary for cellular respiration and growth, and a sparger provides a means of introducing oxygen into the culture medium.

3. What types of spargers are there?

There are several types of spargers, including sintered metal spargers, ceramic spargers, and frit spargers. The type of sparger used depends on the specific requirements of the bioreactor and the process being used.

4. How does a sparger work?

A sparger works by introducing gas into the bioreactor through a porous material. The gas then bubbles through the culture medium, providing oxygen to the microorganisms or cells.

5. What are some factors to consider when selecting a sparger?

Some factors to consider when selecting a sparger include the size of the bioreactor, the type of microorganisms or cells being grown, the desired oxygen transfer rate, and the availability of the gas being used.

6. How can the performance of a sparger be optimized?

The performance of a sparger can be optimized by selecting the appropriate sparger type and size, controlling the flow rate of the gas, and ensuring that the sparger is properly positioned in the bioreactor.

7. Can a sparger be used for other gases besides oxygen?

Yes, spargers can be used to introduce other gases, such as carbon dioxide or nitrogen, into a bioreactor. The type of gas used depends on the specific requirements of the process being used.

8. What is the effect of sparger design on bioreactor performance?

The design of the sparger can have a significant impact on the performance of the bioreactor. Factors such as sparger size, shape, and porosity can affect the rate of gas transfer, mixing, and shear stress in the culture medium.

9. What is the role of sparger placement in a bioreactor?

The placement of the sparger in a bioreactor can affect the distribution of gas and the mixing of the culture medium. Proper sparger placement is important for achieving uniform oxygen transfer and maintaining a homogeneous culture.

10. Can sparger fouling affect bioreactor performance?

Yes, sparger fouling can affect bioreactor performance by reducing the rate of gas transfer and altering the mixing of the culture medium. Regular cleaning and maintenance of the sparger can help prevent fouling.

11. How does sparger design affect shear stress in a bioreactor?

Sparger design can affect the shear stress in a bioreactor by altering the rate of mixing and the size and distribution of bubbles. High shear stress can be detrimental to some microorganisms or cells, so sparger design should be carefully considered.

12. What is the impact of sparger type on gas bubble size?

The type of sparger used can affect the size of gas bubbles produced. Ceramic and frit spargers tend to produce smaller bubbles, while sintered metal spargers tend to produce larger bubbles.

13. How does sparger design affect oxygen transfer rate?

Sparger design can affect the oxygen transfer rate by altering the surface area available for gas transfer and the size and distribution of bubbles. Factors such as sparger porosity and gas flow rate can also impact the oxygen transfer rate.

14. Can sparger design impact cell viability or product yield?

Yes, sparger design can impact cell viability or product yield by affecting factors such as oxygen transfer rate, shear stress, and mixing. Improper sparger design can lead to poor cell growth or product yield, so careful consideration of sparger design is important.

15. What are some common challenges associated with sparger use in bioreactors?

Common challenges associated with sparger use include fouling, uneven gas distribution, excessive shear stress, and difficulty controlling gas flow rates. Regular maintenance and monitoring can help mitigate these challenges and ensure optimal bioreactor performance.

16. What is the impact of sparger design on gas holdup in a bioreactor?

Sparger design can affect the gas holdup in a bioreactor by altering the size and distribution of bubbles. The amount of gas in the culture medium can impact factors such as mixing, oxygen transfer rate, and shear stress.

17. How does sparger design impact the formation of foam in a bioreactor?

Sparger design can impact the formation of foam in a bioreactor by altering the rate of gas introduction and the size and distribution of bubbles. Sparger design can also impact the distribution of nutrients and cells in the culture medium, which can impact foam formation.

18. Can sparger design impact the pH of the culture medium in a bioreactor?

Yes, sparger design can impact the pH of the culture medium by altering the rate of gas introduction and the mixing of the culture medium. Careful consideration of sparger design and gas flow rates can help maintain a stable pH in the culture medium.

19. How can the size of the sparger impact bioreactor performance?

The size of the sparger can impact bioreactor performance by affecting factors such as gas transfer rate, mixing, and shear stress. A larger sparger can provide a greater surface area for gas transfer, but may also increase shear stress in the culture medium.

20. What is the impact of sparger design on energy consumption in a bioreactor?

Sparger design can impact energy consumption in a bioreactor by affecting the rate of gas transfer and the mixing of the culture medium. Efficient sparger design can help reduce energy consumption while still providing adequate oxygen transfer and mixing.

Conclusion

In conclusion, spargers play a critical role in providing oxygen and mixing in bioreactors. The selection and design of a sparger depend on several factors, including the type of bioreactor, gas flow rate and pressure, vessel geometry, and process requirements. Regular cleaning and maintenance of the sparger are essential to prevent fouling and ensure efficient operation. Spargers are used in a variety of industrial and research applications, including pharmaceutical production, bioremediation, wastewater treatment, and food and beverage production.

Are you interested in optimizing your bioreactor performance?

If so, consider incorporating a sparger into your system. Spargers are devices used to introduce gases into bioreactors, promoting better mixing and aeration of the culture medium, which can lead to improved cell growth and production.

By using a sparger in your bioreactor, you can increase the dissolved oxygen concentration, which is essential for many cell types to thrive. Additionally, spargers can help to distribute nutrients evenly throughout the bioreactor, preventing the buildup of harmful byproducts and reducing the risk of cell death.

If you want to take your bioreactor performance to the next level, consider investing in a high-quality sparger.

Contact us today to learn more about how spargers can benefit your bioreactor operations.

Send your message to us: