What is Humidity Transmitter ?

What is Humidity Transmitter?

Humidity transmitter, also known as Industry Humidity Sensor or humidity-dependent sensor, is a device that detects the relative humidity of the measured environment and converts it into electrical signal output, so as to meet the needs of users’ environmental monitoring.

What is the Working Principle of Humidity Transmitter?

Humidity sensor is used for humidity detection and temperature transmitter is usually polymer humidity sensitive resistor or polymer humidity sensitive capacitor, the signal of humidity sensor is converted by humidity transmitter into standard current signal or standard voltage signal through conversion circuit.

What are the Categories of Humidity Transmitter?

Humidity transmitter is mainly used to measure the humidity of the environment. It is displayed in digital form on the display screen. The transmitter converts the humidity signal into analog signal, and can also respond to the command issued by the host, and upload the measured data in the form of data packets through the RS485 bus to the host. From the product structure, humidity transmitter can be divided into split type and integrated type, the main difference is whether the probe is built in. If the probe is built-in, the transmitter is an integrated humidity transmitter. If the probe is external, the transmitter is a split transmitter. The split structure can be divided into bracket mounting type and thread mounting type according to the installation of the probe.

1. Split Type

HENGKO HT802P Temperature and Humidity Transmitter, Split design, Humidity Sensor probe + Wire Connector + Transmitter

HT-802P series is a digital output temperature and humidity transmitter with RS485 interface, following the Modbus protocol. It adapts to DC 5V-30V power supply voltage, and low power design greatly reduces the self-heating impact. The two installation methods of mounting ears and screw is greatly convenient for the quick installation of transmitter in a variety of places. The transmitter provides an RJ45 connector and a shrapnel crimp terminal for quick wiring, cascading and maintenance.

Its features include: wide measurement range, high accuracy, short response time, good stability, multiple output, small and delicate design, convenient installation and external I²C probe.

Main applications: stable indoor environment, HAVC, indoor swimming pool, computer room, greenhouse, base station, meteorological station and warehouse.

2. Integrated Type

HENGKO HT800 Series Integrated Temperature and Humidity Transmitter

HT-800 series temperature and humidity probe adopts HENGKO RHTx series sensors. It can collect temperature and humidity data at the same time. Meanwhile, it has the characteristics of high precision, low power consumption and good consistency. The collected temperature and humidity signal data and the dew point data can be calculated at the same time, which can be output through the RS485 interface. Adopting Modbus-RTU communication, it can be networked with PLC, man-machine screen, DCS and various configuration software to realize temperature and humidity data acquisition.

Main applications: cold storage temperature and humidity data collection, vegetable greenhouse, industrial environment, granary and so on.

What Are the Main Applications of Humidity Transmitter?

Civil Use

Anyone who owns a house knows that excessive moisture in a home can lead to the rapid growth of mold, which is one of the main causes of unhealthy indoor air quality. It can exacerbate asthma and other potential respiratory diseases, and damage wood floors, wall panels, and even structural elements of a house. Few realize that maintaining optimal humidity levels in your home is also a way to reduce the spread of bacteria and virus-related infections.

A humidity deficit of about 5 to 10 percent can also cause discomfort to our bodies and homes. At relative humidity levels of about 5%, many people may experience uncomfortably dry skin and sinus problems. Persistent low humidity levels can also cause wood in our homes to dry out rapidly, which can lead to warping and cracking. This problem may affect the tightness of the building structure and lead to air leakage, thereby reducing thermal performance and energy efficiency.

Therefore, the temperature and humidity transmitter is important for monitoring the humidity of the home environment. For the situation of mold production caused by humidity in the home, the humidity transmitter allows you to monitor any relative humidity level above 50% to 60% and make the necessary changes to reduce this level. If health issues arise due to high or low humidity levels, such as sinusitis, the humidity transmitter can let you know when the relative humidity level is below a trigger threshold (e.g. 10% to 20%). Similarly, for people who suffer from asthma or are extremely sensitive to mold, humidity transmitter can also let you know when your home humidity levels may be contributing to these types of health issues. For homeowners who want to test the effectiveness of different ventilation and humidity control strategies, humidity transmitters can help homeowners quickly determine if humidity control strategies are working.

Industrial Use

① Application of temperature and humidity transmitter in vaccine cold chain storage and transportation

Vaccine storage must have strict temperature control standards, and the formal vaccine storage and distribution chain should be equipped with temperature and humidity monitoring equipment throughout the whole process to meet the requirements of the Good Supply Practice (GSP). Therefore, the participation of temperature and humidity transmitter is essential. Temperature monitoring is recorded and recorded throughout the cold chain during vaccine storage, transportation and distribution. When checking each batch of goods, the CDC must check the temperature and humidity records on the way at the same time, and confirm that the temperature records during transportation meet the relevant provisions of GSP before acceptance and warehousing.

The combination of temperature and humidity transmitter and electronic tag technology provides an excellent solution for temperature and humidity monitoring and measurement in such applications. Electronic tag is an information carrier chip that adopts RF technology for near distance communication. It is compact in size, convenient in installation and use, and very suitable for information labeling and discrimination of scattered items.

The temperature and humidity transmitter is integrated into an electronic tag so that the electronic tag can measure the temperature and humidity of the installed object or application environment. The measured values are transmitted to the reader in RF mode, and then the reader sends the measured values to the application background system in wireless or wired mode.

Through computer or mobile APP, personnel of department of vaccine management of CDC can check real-time temperature and humidity data transmitted by the T/H sensors on the cold chain equipment like refrigerator or cold chain transporter in whole district or the unit anytime and anywhere. Meanwhile, personnel can retrieve historical temperature records of cold chain equipment at any time to accurately grasp the running status of cold chain equipment in any time period

equipment running status. In case of power failure and other emergencies, the management personnel will receive the alarm message in the first time and deal with it in time to minimize the loss of vaccines caused by the cold chain temperature.

② Application of temperature and humidity transmitter in intelligent agriculture monitoring

“Intelligent agriculture” is an integrated technology system that applies computer and network, Internet of Things, wireless communication and other technologies to realize the functions of fine management, remote control and disaster warning of modern agricultural production. In this process, if the soil moisture transmitter is lower than 20% for a long time, the whole system will give an early warning to the headquarters of the enterprise.

Temperature and humidity transmitter promotes the construction of “intelligent greenhouse”. Technicians at home through the computer or mobile phone, can directly control the command. If the temperature in the greenhouse is found to have exceeded 35 ℃, the technician can directly open the fan in the whole facility through the remote control of the mobile phone. When the soil moisture is below 35%, start spraying irrigation and replenishing water immediately and people can control this area at any time and anywhere. Using the greenhouse model, the intelligent greenhouse remote management mode is realized.

③Application of temperature and humidity transmitter in supermarket food preservation

In the field of food safety, in addition to being an important part of greenhouse temperature and humidity monitoring system, temperature and humidity sensor is also very important for food temperature and humidity regulation in supermarkets.

Because of the peculiarities of supermarkets, not all foods sell well, and some need to be kept longer. At this time, the control and management of temperature and humidity is particularly important, if the temperature and humidity are too low, especially low fruit storage temperature and humidity will cause changes of the food flavor and quality as well as physiological diseases. High temperature and humidity is the hotbed of mold production, causing food decay. Therefore, the need for appropriate temperature and humidity is more conducive to the preservation of food. In the storage link, it is required that the storage temperature of fresh vegetables and fruits should be controlled at 5-15 ℃, the frozen food should be stored in the freezer below -18 ℃ , and the temperature of the hot cabinet should be above 60 ℃, etc.

To prevent the influence of humidity and temperature, the temperature and humidity sensor plays an important role. It helps the management personnel record the change of temperature and humidity at all times, and ensures that the managed items can be stored for a long time in the equipment room and archive room.

How to Choose a Humidity Transmitter for Your Project ?

For this question, at first, we need to know details about your application, because we will introduce you different humidity transmitter based on your specific application.

① Greenhouse

If you are puzzled by the difficulty of humidity measurement in greenhouse, we can recommend the HENGKO HT 802P temperature and humidity transmitter.

HT-802P series is a digital output temperature and humidity transmitter with RS485 interface, following the Modbus protocol. It adapts to DC 5V-30V power supply voltage, and low power design greatly reduces the self-heating impact. With a temperature accuracy of ±0.2℃ (25℃) and humidity accuracy of ±2%RH (10%RH~90%RH, 25℃), it can help you monitor the temperature and humidity of the greenhouse accurately. The environmental temperature and humidity ranges are -20~85℃ and 10%~95%RH respectively. With an LCD display, it is convenient for you to get the reading.

② Cold Chain

If you are worried about whether the temperature and humidity are suitable during transportation and don’t know how to measure the temperature and humidity accurately, the HENGKO HT802 C temperature and humidity transmitter will be your first option.

HT-802C intelligent temperature and humidity transmitter is a kind of intelligent transmitter to detect and collect environmental temperature and humidity. The transmitter adopts a large LCD screen to display the temperature, humidity and dew point value of the current environment in real time. HT-802C can communicate with computer through RS485 serial communication interface to realize remote monitoring of temperature and humidity transmitter.

With a temperature accuracy of ±0.2℃ (25℃) and humidity accuracy of ±2%RH (10%RH~90%RH, 25℃), it can help you monitor the temperature and humidity during transportation accurately. The environmental temperature and humidity ranges are -20~85℃ and 10%~95%RH respectively. With a large LCD display and built-in probe, it is convenient for you to install the transmitter and get the reading.

③Chemical Plant

If you are in the need of temperature and humidity measurement of chemical plant, the HENGKO HT 800 series integrated temperature and humidity transmitter is recommended.

HT-800 series temperature and humidity probe adopts HENGKO RHTx series sensors. It can collect temperature and humidity data at the same time. Meanwhile, it has the characteristics of high precision, low power consumption and good consistency. The collected temperature and humidity signal data and the dew point data can be calculated at the same time, which can be output through the RS485 interface. Adopting Modbus-RTU communication, it can be networked with PLC, man-machine screen, DCS and various configuration software to realize temperature and humidity data acquisition.

With a temperature accuracy of ±0.2℃ (25℃) and humidity accuracy of ±2%RH (10%RH~90%RH, 25℃), it can help you monitor the temperature and humidity of the chemical plant accurately. You can get the reading from the external output device if it’s inconvenient for you to enter the chemical plant for temperature and humidity reading.

What Is Relative Humidity? Why Is Relative Humidity So Important in Daily Measurement?

The relative humidity (RH) of an air-water mixture is defined as the ratio of the partial pressure of water vapor () in the mixture to the equilibrium vapor pressure of water ()over a flat surface of pure water at a given temperature:

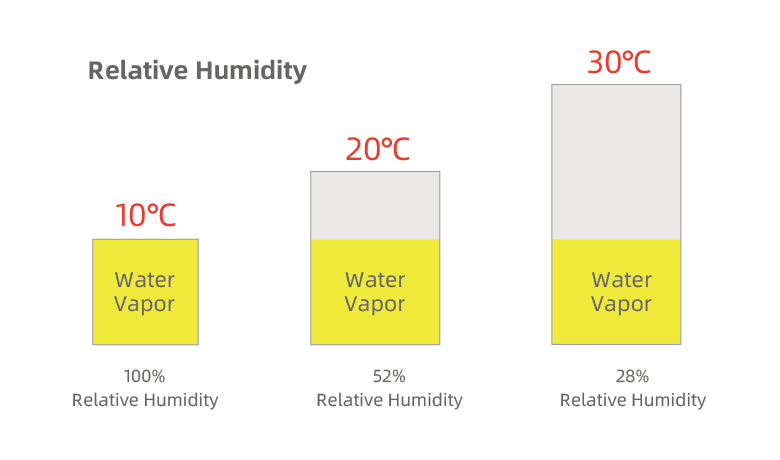

In other words, relative humidity is the ratio of the amount of water vapour in the air to the amount of water vapor that the air might contain at a given temperature. It varies with the temperature: colder air can hold less vapour. Thus changing the air temperature will change the relative humidity even if the absolute humidity remains constant.

Cold air increases the relative humidity and can cause the water vapour to condense (the saturation point if relative humidity rises more than 100%). Similarly, warmer air decreases the relative humidity. Heating some of the air containing the fog may cause the fog to evaporate, as the air between the water droplets becomes more capable of holding water vapour.

Relative humidity only considers the invisible water vapour. Mists, clouds, fogs and water aerosols are not counted in measurements of relative humidity of the air, although their presence indicates that the body of air may be close to the dew point.

Relative humidity is usually expressed as a percentage; a higher percentage means that the air–water mixture is more humid. At 100% relative humidity, the air is saturated and at the dew point. In the absence of a foreign body that can nucleate droplets or crystals, the relative humidity can exceed 100%, in which case the air is said to be supersaturated. Introducing some particles or a surface into a body of air with relative humidity above 100% will allow condensation or ice to form on those nuclei, thereby removing some of the vapor and reducing the humidity.

Relative humidity is an important metric used in weather forecasts and reports, because it is an indicator of the likelihood of precipitation, dew, or fog. In hot summer weather, an increase in relative humidity blocks the evaporation of sweat from the skin, raising the apparent temperature to humans (and other animals). For example, at an air temperature of 80.0 °F (26.7 °C), 75% relative humidity feels like 83.6 °F ±1.3 °F (28.7 °C ±0.7 °C), according to the Heat Index.

By far the biggest reason for monitoring relative humidity is to control moisture around the final product. In most cases this means ensuring that RH never rises too high. For example, let’s take a product such as chocolate. If the RH in a storage facility rises above a certain level and stays above that level for a sufficiently long time, a phenomenon called blooming can occur. This is where moisture forms on the surface of the chocolate, dissolving the sugar. As the moisture evaporates, the sugar forms larger crystals, leading to discoloration.

Humidity can also have a serious and costly impact on products such as building materials. Let’s say you’re expanding your property and laying a concrete subfloors before hardwood flooring. If the concrete isn’t sufficiently dry before the floor is laid, it can cause huge problems, as any moisture in the concrete will naturally try to migrate to a drier area, in this case the flooring material. This can cause the floor to swell, blister, or crack, leaving all your hard work and leaving no option except replacement.

Humidity is also a big problem for products that are extremely sensitive to moisture such as certain pharmaceuticals. This is because it can change the characteristics of the product until it becomes useless, which is why products like pills and dry powders are stored under controlled conditions at precise humidity and temperature levels.

Finally, relative humidity is also an important factor for building automation systems that focused on human comfort, such as air conditioning. The ability to measure and control relative humidity not only helps maintain a comfortable environment inside a building, but it also helps optimize the efficiency of an HVAC systems, as it can indicate how much outside air needs to be regulated, depending on the temperature outside.

If you also have museum project need to control the Temperature and Humidity, you are welcome to contact us for details, or you can send email by ka@hengko.com, we will send back within 24-hours.