Full Guide About What is Sintered Metal Filter ?

What is Sintered Metal ?

What is Sintered Filter Working Principle ?

Short to say, Because of the stable porous frame, sintered metal filters are one of the better filtration elements

nowadays. Also, the metal materials' high temperature, high pressure, and corrosion resistance can help you

easily complete the filtering task in a harsher environment, Separating and filtering out excess impurities

you don't need or helping you extract higher purity gases or liquids for your project, and if you are also looking

some real factory to OEM sintered metal filter for your filtration system, please check here to find

the Top Industrial Filters Manufacturers.

Maybe You Should not hear this word much in your daily life.

But nowadays, sintered metal to use more and more in various industries, the sintered metal has started to become

the key technology in some manufacturing.

Then What Exactly is a Sintered Metal ?

Actually, it is a branch of the powder metallurgy industry, in short, is the 316L stainless steel powder through the mold

shaping, high temperature sintering into the shape and function of a process that we need.

Then, Firstly, sintered. What is sintered?

Sintering is the process of compacting and forming a solid mass of material

by heat or pressure without melting it to the point of liquefaction. Sintering is part of a manufacturing process used

with metals, ceramics, plastics, and other materials. Wikipedia

As Wikipedia describes, many kinds of materials can be sintered, and different materials sintered products have

different applications. Then here we like to talk more details about sintered metal.

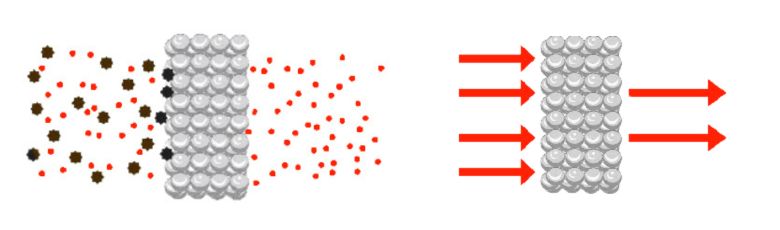

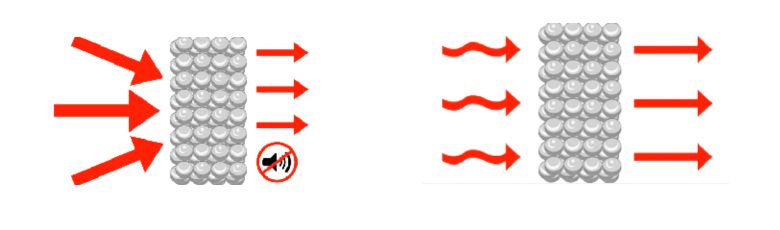

1. Filtration and Separation 2. Fluid restrictions

3. Noise reduction 4. Stable flow

History of Sintering Metal

Who Inventions the sintering and started to use the sintered products?

According to historical records, the sintering process emerged during the second industrial revolution 18th century

in Sweden and Denmark. Sintered iron was found during the smelting process in coal mines. But till 1980, people

started to use the sintered metal to the filtering oil. And for 1985, the first used HyPulse® filtration technology for

continuous slurry oil filtration.

So actually, you can check as following, there are main 3-developing time.

So actually, you can check as following, there are main 3-developing time.

1.Ancient Origins

*Bronze Age:

The earliest evidence of sintering-like processes dates back to the Bronze Age, where metal objects were

likely formed by heating and compressing metal powders.

*Iron Age:

Ironworking techniques, including the use of heated and compressed iron ore, may have incorporated

elements of sintering.

2.Industrial Revolution and Early Developments

*19th Century:

The Industrial Revolution saw increased interest in metalworking techniques. Powder metallurgy,

a precursor to sintering, began to emerge as a method for producing metal objects from powdered materials.

*Early 20th Century:

Advancements in metallurgy and materials science led to further developments in sintering techniques.

The production of porous metal filters and bearings using sintering processes became more common.

3.Modern Era and Technological Advancements

*Mid-20th Century:

Sintering technology experienced significant growth during the mid-20th century, driven by advancements

in powder metallurgy and materials science. The development of high-performance sintered materials for

aerospace, automotive, and industrial applications became a focus.

*Late 20th and Early 21st Centuries:

The late 20th and early 21st centuries witnessed continued innovation in sintering technology. The development

of advanced sintering techniques, such as selective laser sintering (SLS) and binder jetting, expanded the range

of materials and complex shapes that could be produced.

Contemporary Applications

*Automotive:

Sintered materials are widely used in automotive components, including gears, bearings, and filters.

Their properties, such as strength, durability, and porosity, make them ideal for demanding applications.

*Aerospace:

Sintered materials are used in aerospace components due to their lightweight, high-strength properties.

They are found in parts such as turbine blades, fuel nozzles, and heat exchangers.

*Medical Devices:

Sintered materials are used in a variety of medical devices, including implants, prosthetics, and dental components.

Their biocompatibility and customizable properties make them suitable for these applications.

*Industrial Applications:

Sintered materials have numerous industrial applications, including in filtration, electronics, and energy storage.

Their versatility and performance characteristics make them valuable in a wide range of industries.

Conclusion

Anyway, Sintering technology has evolved significantly over centuries, from its ancient origins to its modern-day applications.

Through continuous advancements in materials science and manufacturing processes, sintered materials have become

essential components in various industries, contributing to technological progress and innovation.

So What is Sintered Metal Filter ?

A simple definition of sintered metal filter:

It is a metal filter that uses metal powder particles of the same particle size to be shaped by a stamping,

high-temperature sintering process. Sintering is the process of metallurgy using powder-sized bodies of

different metals and alloys after stamping.

Metallurgy occurs by diffusion at temperatures below the melting point of high-temperature furnaces.

The metals and alloys commonly used today include aluminum, copper, nickel, bronze, stainless steel,

and titanium.

There are different processes you can use to form the powder. They include grinding, atomization,

and chemical decomposition.

What the Sintering Metal Filter Manufacturing Process

Then, so here, we like to check the process detail of Metal filter manufacturing. if interested, please check below:

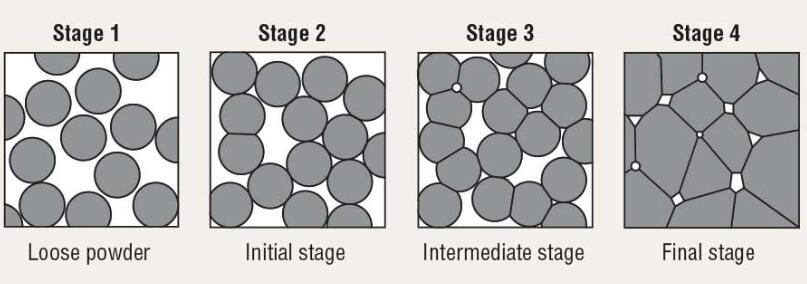

1.) What is Sintering, Why Use Sintering?

Simple definition sintering is metal powder is bonded together by high temperature and other methods into

the desired module. In the micron range, there is no physical limitation between the metal powder particles,

which is why we can control the pore distance

through the production process.

The porous cartridge of the sintering process provides the stable shape of the metal and provides

the material with the performance of robust filtration.

2.) 3-Main Steps of Sintered Metal Filter Manufacturing

A: First Step is To Get the Power Metal.

The metal powder, You can obtain metal powders by grinding, atomization, or chemical decomposition.

You can combine one metal powder with another metal to form an alloy during the fabrication process,

or you can use only one powder. The advantage of sintering is that it does not change the physical

properties of the metal material. The process is so simple that the metal elements are not altered.

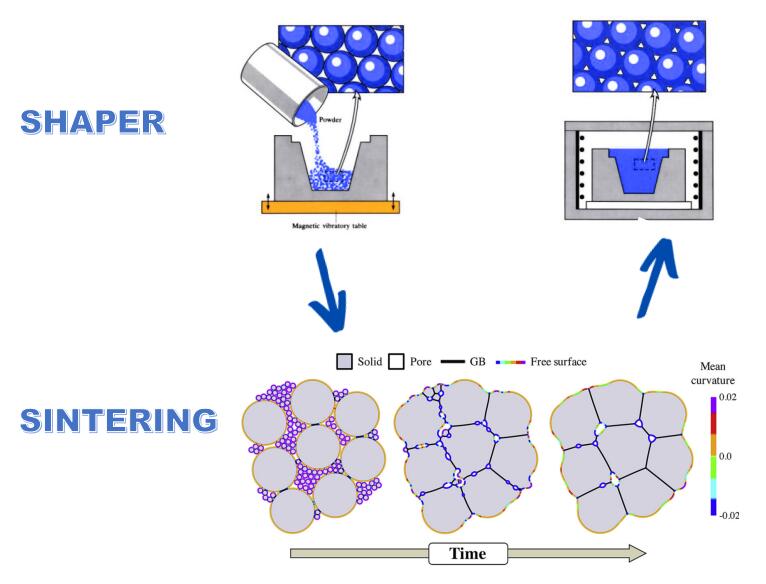

B: Stamping

The second step is to pour the metal powder into a pre-prepared mold in which you can shape the filter.

The filter assembly is formed at room temperature and under stamping. The amount of pressure applied

depends on the metal you are using, as different metals have different elasticity.

After a high-pressure impact, the metal powder is compacted in the mold to form a solid filter. After the

high-pressure impact procedure, you can place the prepared metal filter in a high-temperature furnace.

C: High-temperature Sintering

In the sintering process, the metal particles are fused to form a single unit without reaching the melting point.

This monolith is as strong, rigid, and porous a filter as the metal.

You can control the porosity of the filter by the process according to the flow level of the air or liquid to be filtered.

The sintered media grade designation is equivalent to the mean flow pore, or average pore size of the filter.

Sintered metal media are offered in grades 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 and 100. The filtration rating in

liquid for media grades 0.2 to 20 is between 1.4 and 35 µm absolute. The filtration rating in gas ranges

from 0.1 to 100 µm absolute.

Why to Use Metal Sintering to Make Filter?

This is a good question, why use metal to make a filter?

The answer is simple, and although there are many reasons, the cost is the most important.

Why Cost ?

Yes, the sintered metal has a stable structure and can be reused, clean, and used many times.

And also, different metals have stable physical and chemical properties and are not easily damaged.

It is why more and more Sintered Filters are used in different industries.

What are the Material Choices for Sintered Filters?

With the continuous progress of powder metallurgy technology, there are more choices of

materials for sintered metal filters,

You can choose from many other metals and alloys to meet special requirements of higher

temperature and pressure, corrosion resistance etc , Main metal materials such as :

-

Stainless Steel Filter; 316L, 304L, 310, 347 and 430

-

Bronze

-

Inconel® 600, 625 and 690

-

Nickel200 and Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Alloys

Sintered stainless steel filters, including filter cartridges, plates, and tubes made from stainless steel

304 and 316, offer high filtering efficiency, long service life, and versatility in applications for both liquid

and gas filtration. They perform well in high-temperature and corrosive environments.

More and more metal will be used in the future.

8-Main Advantages of Sintered Metal Filter

1. ) Corrosion resistance

Most metals are inherently resistant to corrosion, such as sulfides, hydrides, oxidation, etc.

2. ) More effective removal of contaminants

Adjusting the porosity of the cartridge to the fluid means you can achieve the perfect

filtration you want and get a contaminant-free fluid. Also, since the filter does not corrode,

the filter's reaction does not result in the presence of contaminants in the fluid.

3. ) High Thermal Shock

During the manufacturing process, high heat is generated, and the physical properties of

these metals help absorb the filter's great thermal shock. As a result, you can use these

filters in a wide range of applications depending on the thermal range of the application.

Great thermal shock also ensures effective fluid filtration without having to worry about

the heat of the application.

4、) Reasonable Pressure Drop

A sintered metal filter can maintain fluid pressure in your application, thus ensuring

maximum operation.

A slight pressure drop can harm your application.

5. ) Temperature and Pressure Resistance

You can use this filter in applications with high temperatures and pressures without

worrying about your filter element.

Using sintered metal filters in the production process of chemical reactions and gas

treatment plants ensures you get the best filtration results.

6. ) Tough and Resistant to Breakage

Another benefit of using a sintered metal filter is that it is strong and resistant to

fracture.

During the manufacturing process, the bonding of metals occurs at temperatures well

below the melting point.

The resulting product is a tough sintered metal filter that can withstand various

harsh environments.

For example, you can use it in applications requiring friction without fear of breakage.

7.) Fine Tolerances

Fine tolerances mean that your sintered metal filter can filter your fluid without reacting.

Once your filtration is complete, the sintered metal filter will retain its physical properties.

However, it would help if you made sure that the metal you choose for your filter will not

react with the fluid you are filtering

8.) A range of Geometric Possibilities

Sintered cartridges allow you to enjoy a wide range of geometric options. You can achieve

this while inserting the powder into the dye during manufacturing.

The mold is the one that should design your filter.

Therefore, you are free to operate the design according to your specifications.

For example, if your application requires a small filter, you can easily manipulate the design

to obtain a smaller

sintered metal filter. Likewise, if your application has a distinctive design, you can easily

manipulate the design in the mold during manufacturing.

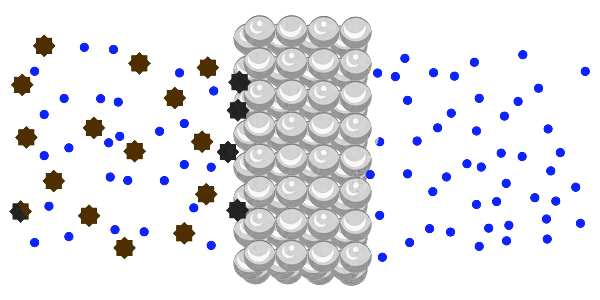

How Sintered Metal Filters Work?

This problem can also be said to be the working principle of sintered metal filters. Many people think

that this question is very difficult to answer, and it is not. You may be surprised by this, but maybe you

won't be after reading my explanation.

Sintered metal filters are very useful filters. The collection of contaminants occurs on the surface of

the fluid; when the fluid passes through the metal filter, the large particles and contaminants will be

left on one side of the cartridge, but when choosing an effective filtration level for your fluid, you

need to make sure that it can even filter the requirements.

*These Requirements Include

1. Contaminant Retention Backwash Capability

2. Pressure Drop

For pressure drop, you need to consider several factors.

These factors include

A Fluid viscosity, fluid velocity as it flows through the filter element, and contaminant characteristics.

B Contaminant characteristics include particle shape, density, and size.

If the contaminant is hard and regular in shape, forming a dense cake, then surface filtration is appropriate.

*The Effectiveness of Sintered Metal Filtration Depends on

1. the increased pressure drops to the point where the absolute pressure is reached.

2. the constant flow of the fluid.

You can achieve end conditions by thickening contaminants that increase to the point where the fluid pressure drops.

This pressure drops continuously until the maximum drop for a given viscosity and flow rate requirement is reached.

Another important issue is the back washing of the filter, which is performed by pressurizing the gas to the screen and rapidly

opening the backwash discharge valve as the backwash occurs.

A high reverse instantaneous pressure differential is generated. It effectively removes contaminants from the filter

element surface. The reverse flow of clean fluid through the filter element removes contaminants and directs them

out of the filter.

The steady rise in pressure drop rate indicates a consistent and uniform distribution of contaminant size. To

achieve consistent performance, you must ensure that the filter element's pressure drop is stable. If the temperature

of the fluid changes, it affects the viscosity of the fluid. In this case, the pressure drop across the filter element will

increase and not achieve the filtration effect.

Therefore, you need to maintain the working temperature of the filter during the filtration process and

ensure the temperature of the fluid and the pressure. When cleaning the filter, you need to follow the

correct back washing procedure.

How the Sintered Metal Filters Works ?

You can easy to understand when you check the follow Working principle diagram

As follow is main 8-Kinds of The working principle of metal filtration, hope it will be helpful for you to

understand more for how sintered metal Filter can help for filtration liquid, gas and voice.

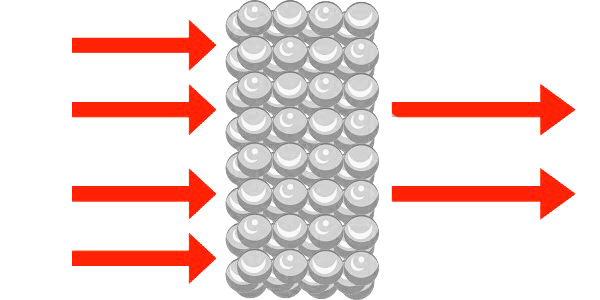

1.) Liquid & Gas Filtration/Separation

Sintered Metal filters can reduce or completely remove particulate matter from a gas or liquid medium.

Particulate matter can include but is not limited to suspended particles (sediment, metal chips, salt, etc.),

algae, bacteria, fungi spores, and unwanted chemical/biological contaminants. Metal filter pore sizes

can make to be range from 0.2 µm – 250 µm.

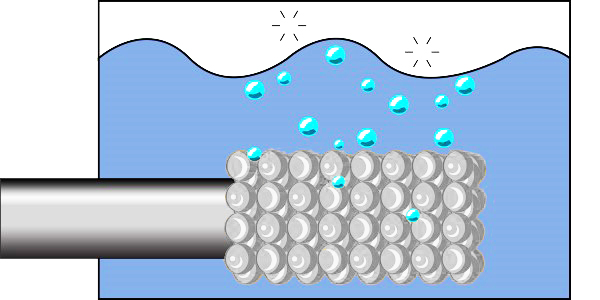

2.) Sparger

Some of Sparging Applications :

Soda Carbonization

Beer Carbonization

Oxygen Stripping of Edible Oils

Sparging is the introduction of a gas into a liquid. It is used to either remove an unwanted dissolved gas

(oxygen stripping) or a dissolved volatile liquid. It can also use to introduce a gas into a liquid (carbonization).

Traditional sparging created bubbles with a diameter of 6 mm. PM filter sparging allows for an even smaller

bubble diameter, thus increasing the surface area of the bubbles creating a more efficient sparging

application by decreasing process time.

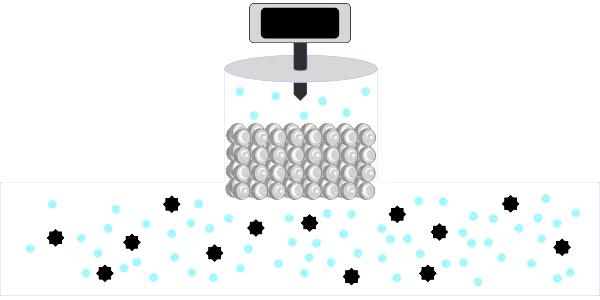

3.) Breather Vents

Sintered metal filters are also used as breather vents in cylinders, gearboxes, manifolds, hydraulic systems,

reservoirs, and other systems. Breather vents allow pressure equalization and air/gas in and out of a system

while blocking particulate matter from entering the system. Sintered bronze filter discs are particularly effective

in electric motors, preventing the entry of dust, moisture, and other contaminants while still allowing for air

exchange, which is crucial for maintaining the internal environment of the motor and ensuring its proper

functioning and longevity. Metal filters can be back washed to remove particulate matter, giving them a longer

lifespan as a breather vent than other filter media.

4.) Sensor Protection

Sintered Metal Filters can also protect electronic components as a cover, such as thermometers,

various sensors, key components of medical systems, and other sensitive products from water,

liquids, sediment, dust, and pressure fluctuation.

5.) Flow Control ( Throttling / Dampening )

A special sintered filter can control the flow within an air, gas, vacuum, and fluid flow system. The

filter's uniform pore sizes allow for consistent, repeatable flow regulation and protect valves, sensors,

and anything else downstream in the system from contaminants. Flow control is used in such

applications as pneumatic timers, gas supply control elements, and time delay elements in

automotive applications.

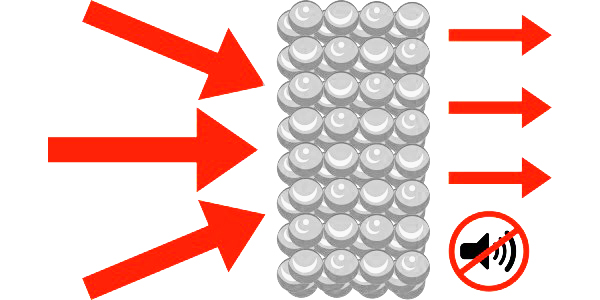

6.) Air Exhaust Silencers

Sintered filters can also be welded or sinter-bonded to any required fitting, allowing them to work as an

exhaust silencer. The filter cannot only protect solenoids and manifolds from contaminants inside the

system but also minimizes the noise level of exhaust from the system. The air exhaust silencer filters

also lower the air blowing out from the system, which minimizes contaminants wafting, Protecting

the environment.

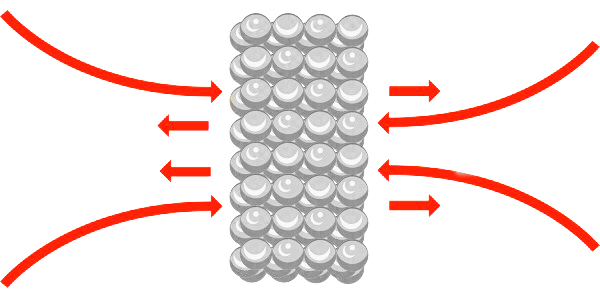

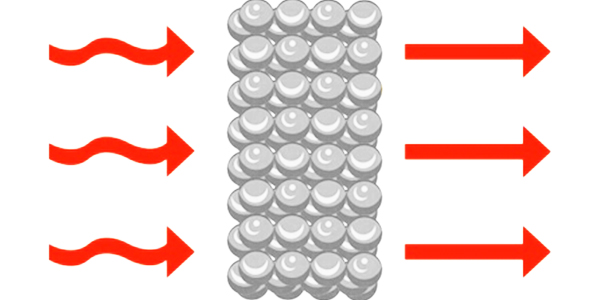

7.) Flow / Pressure Equalization

Sintered filters can equalize and control a system's flow rate and pressure. Equalization protects

systems against a surge of liquid and creates a uniform flow as the gas or liquid moves across

the uniform pores.

What Are Sintered Filters Used For ?

For this question, Actually more people will ask What are the application of sintered metal Filters?

After such a complicated process, where will the sintered metal filter cartridges be used?

The truth is that you can find these filters in various industries.

Common applications include the following.

1) Chemical processing

You can find sintered metal filters in the chemical solvent and gas processing industries, including the

nuclear industry. The corrosion, high temperature, and non-reaction to chemicals make sintered metal

filters a distinct advantage in

the chemical processing industry.

2 ) Petroleum refining

For petroleum refining, to effectively filter different fuels

We need to use different metal filters according to the degree level to complete the filtration of the

specific fuel from the feed stock. Yes, sintered metal filters can help you achieve this goal.

Because metal filters do not react chemically with the fuel.

Therefore, the specific fuel will be free of any contaminants after filtering.

In addition, you can use it at temperatures up to 700°, which is common in petroleum refining.

3.) Power generation

Hydroelectric power generation requires the continuous operation of a turbine. Still, the

environment in which the turbine operates often requires filtration to achieve a body of water in

which the turbine is free of any impurities.

If the turbine is overloaded with impurities, it will wind up and prevent the turbine from rotating,

and then the turbine will not generate electricity. You can use sintered metal filters to ensure

effective and efficient power generation.

These filters are used to generate electricity by filtering water from the turbine.

Because they are not eroded by water, the turbine will work for a long time.

4.) Natural gas production

Another important area of application for sintered metal filters is gas production.

Sintered metal filters are very useful in gas production because they do not react with the gas,

and you can use them in different environments.

5.) Food and beverage

Metal filters extract essential nutrients and juices in the food and beverage processing industry.

Metal filters effectively filter and prevent these nutrients from being washed away during processing.

The advantage of the same metal filters is that they do not react with specific foods or beverages.

When using these filters guarantees the quality of your production process.

9. What kind of Sintered Metal Filters HENGKO Can Supply ?

HENGKO main supply 316L, 316 and bronze sintered metal filers. main shape such as follow list:

1. Stainless Steel Filter Disc,

2. Stainless Steel Filter Tube,

3. Stainless Steel Filter Plate,

4. Stainless Steel Filter Cups,

etc., any shape your project requires.

Sure, we supply O.E.M Service

1. O.E.M Shape : Disc, Cup, Tube, Plate ect

2. Customize Size, Height, Wide, OD, ID

3. Customized Pore Size / Apertures from 0.1μm - 120μm

4. Customize different Thickness

5. Mono-layer, Multi-layer, Mixed Materials

6. Integrated design with 304 stainless steel housing

For Your More O.E.M details, please contact HENGKO Today !

Still Have Any Questions Like to Know More Details For the Humidity Monitoring Sensor ,

Please feel Free To Contact Us Now.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !

Send your message to us: