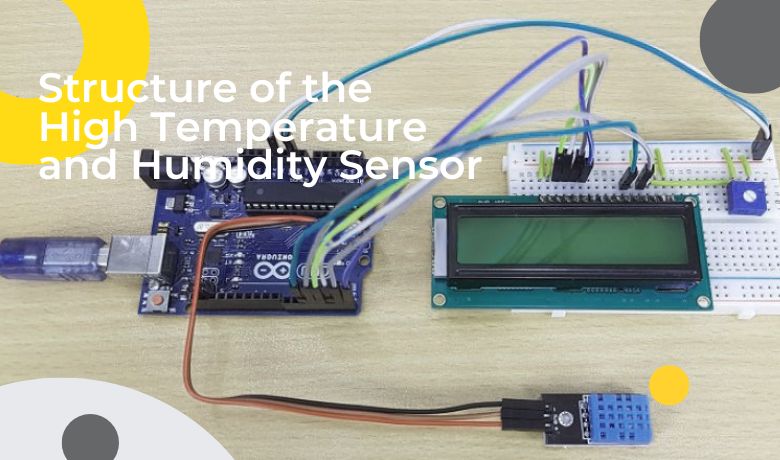

What is the Structure of the High Temperature and Humidity Sensor?

High temperature and humidity sensors are often used in water treatment. Resin filter element is a kind of clean water material made by artificial processing. It is often used in drinking water and clean water filtration. As a filtering product, the filter element is widely used in various industrial environments. Filter elements of different materials are accustomed to different professional needs, and the purchase and use of filter elements is still to choose suitable products based on their own needs.

I. Introduction

Temperature and humidity are two of the most important environmental factors that must monitor in various industries and applications. High temperature and humidity sensors are used to measure these parameters to ensure safety, improve efficiency, and optimize processes. This blog post will discuss the structure of high temperature and humidity sensors, including the different types and components and how they work.

II. Types of High Temperature and Humidity Sensors

Several types of high temperature and humidity sensors are available, each with unique characteristics and advantages. The most commonly used types include:

1.Resistance Temperature Detectors (RTDs):

These sensors use the change in resistance of a material to measure temperature. They are highly accurate and have a wide temperature range, but they are also relatively expensive and fragile.

2. Thermocouples:

These sensors use the electrical potential difference between two dissimilar metals to measure temperature. They are relatively inexpensive and rugged but less accurate than RTDs and have a limited temperature range.

3. Thermistors:

These sensors use the change in resistance of semiconductor material to measure temperature. They are small and inexpensive but less accurate than RTDs and have a limited temperature range.

Regarding humidity, there are a few sensors, such as capacitive, resistive, and optical. Each of them has its advantages and disadvantages.

III. The Components of a High Temperature and Humidity Sensor

The structure of a high temperature and humidity sensor typically includes several key components:

- The sensing element: This is the part of the sensor that measures the temperature and humidity. It can be made of various materials, depending on the type of sensor.

- The signal conditioner: This component converts the electrical signal from the sensing element into a form that can be transmitted and read by other devices.

- The transmitter: This component transmits the signal from the sensor to a remote monitoring or control system.

- The display or output device: This component displays the temperature and humidity readings, typically analog or digital readout.

IV. How High Temperature and Humidity Sensors Work

The operation of a high temperature and humidity sensor depends on the type of sensor used. In general, the sensing element of the sensor will respond to changes in temperature and humidity by altering its electrical properties. The signal conditioner then converts this change in electrical properties into a readable signal. The transmitter then sends this signal to a remote monitoring or control system, where the temperature and humidity readings can be displayed or used to control other devices.

Calibration is a crucial step in the process, and it is to ensure that the sensor accurately measures the temperature or humidity. It can do it by comparing the sensor's readings to a known standard or using a calibration device.

V. Applications of High Temperature and Humidity Sensors

High temperature and humidity sensors have various applications across various industries and environments. Some examples include:

- Industrial settings: High temperature and humidity sensors, such as furnace monitoring, are used in manufacturing processes to ensure that the temperature and humidity levels are within safe limits.

- HVAC systems: These sensors are used in heating, ventilation, and air conditioning systems to monitor and control buildings' and other structures' temperature and humidity levels.

- Weather monitoring: High temperature and humidity sensors are used in meteorological stations to measure the temperature and humidity of the air.

- Agriculture: These sensors are used in greenhouses and other agricultural settings to monitor and control the temperature and humidity levels to optimize plant growth and reduce crop loss.

VI. Conclusion

High temperature and humidity sensors are essential for monitoring and controlling temperature and humidity in various industries and applications.

Several types of sensors are available, each with unique characteristics and advantages. A high temperature and humidity sensor structure typically includes a sensing element, a signal conditioner, a transmitter, and a display or output device.

The operation of these sensors depends on the type of sensor used and is calibrated to ensure accuracy. High temperature and humidity sensors have a wide range of applications, from industrial settings to weather monitoring and agriculture. As technology advances, the accuracy and capabilities of these sensors are continually improving, making them an essential tool for ensuring safety, improving efficiency, and optimizing processes.

Choosing the correct device orientation is very important to ensure the best accuracy and response speed and protect the sensor from damage. According to your measurement area requirements, measure the dew point sensor device in a fixed orientation, such as when the device is at the entrance of the cabinet, the dew point sensor measures It is the dew point of the gas when it enters the box, the gas inside the box itself or any moisture that occurs during work will not be detected.

When the dew point transmitter device is at the gas outlet, the sensor will measure the moisture entering the system through the inlet or leakage and the moisture released during work. HENGKO HT608 series dew point sensor/transmitter have advantage of high precision, low power consumption and good consistency.