Why Does Compressed Air Drying Require Long-term Monitoring of Dew Point Temperature ?

Why need to Care the Dew Point Temperature of the Air Drying ?

Compressed air treatment is a method of dehumidifying and cleaning after leaving the air compressor.The air leaving the compressor is always contaminated by solid particles such as dust, sand, soot, salt crystals and water.An effective compressed air treatment system lowers the dew point of the air and removes elements that can damage equipment downstream of compressors and dryers.Keep in mind that the higher the ambient temperature, the greater the ability to retain moisture.

Water pollution can also lead to microbial contamination, corrosion, blocked or frozen valves, cylinders, pneumatic motors and tools, and premature wear and failure of equipment. Water pollution from compressed air systems can reduce production efficiency and increase manufacturing costs.

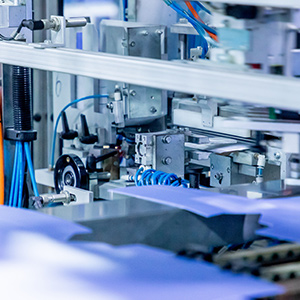

Freeze dryers and desiccant dryers are required in many industrial applications to produce or protect most of the pneumatic equipment used in many industrial facilities.The dryer needs to regularly measure the dew point of the compressed air to ensure the moisture content and avoid the high humidity air causing the final product to malfunction.Almost all compressed air applications require air treatment.From food manufacturing to brewing beer to manufacturing electronics, dry compressed air must be used to prevent damage to products and equipment.

Food and beverage packaging and manufacturing companies use dryers to prevent their actuators and assembly machinery from rusting or accumulating moisture in lines that prevent clean compressed air from flowing.Dryers are also used in textiles to keep the fabric free from moisture and to help produce the texture of the product.Many electronics manufacturers require high levels of dry air so that humidity does not transfer into the production of computers, cell phones, TVs, etc.

Therefore, dew point measurement is very important, can use dew point measuring instrument to dry the inlet and outlet of the dew point temperature detection.The convenient and compact HT-608 series dew point transmitter is your best choice. The stainless steel housing can withstand high pressure, and the small size is convenient for installation.The product has HENGKO RHT series chip inside, which measures accurately and responds quickly. It measures the dew point temperature in time and transmits it to the terminal for the manager's reference.

If You Also Have Compressed Air Drying, It's Better to Install Temperature and Humidity Sensor To Long-term Monitoring of Dew Point Temperature,

Have Any Questions, Please Feel Free To Contact us by Email ka@hengko.com